Efficient Epoxy Dispensing: Tips and Tricks for Optimal Results

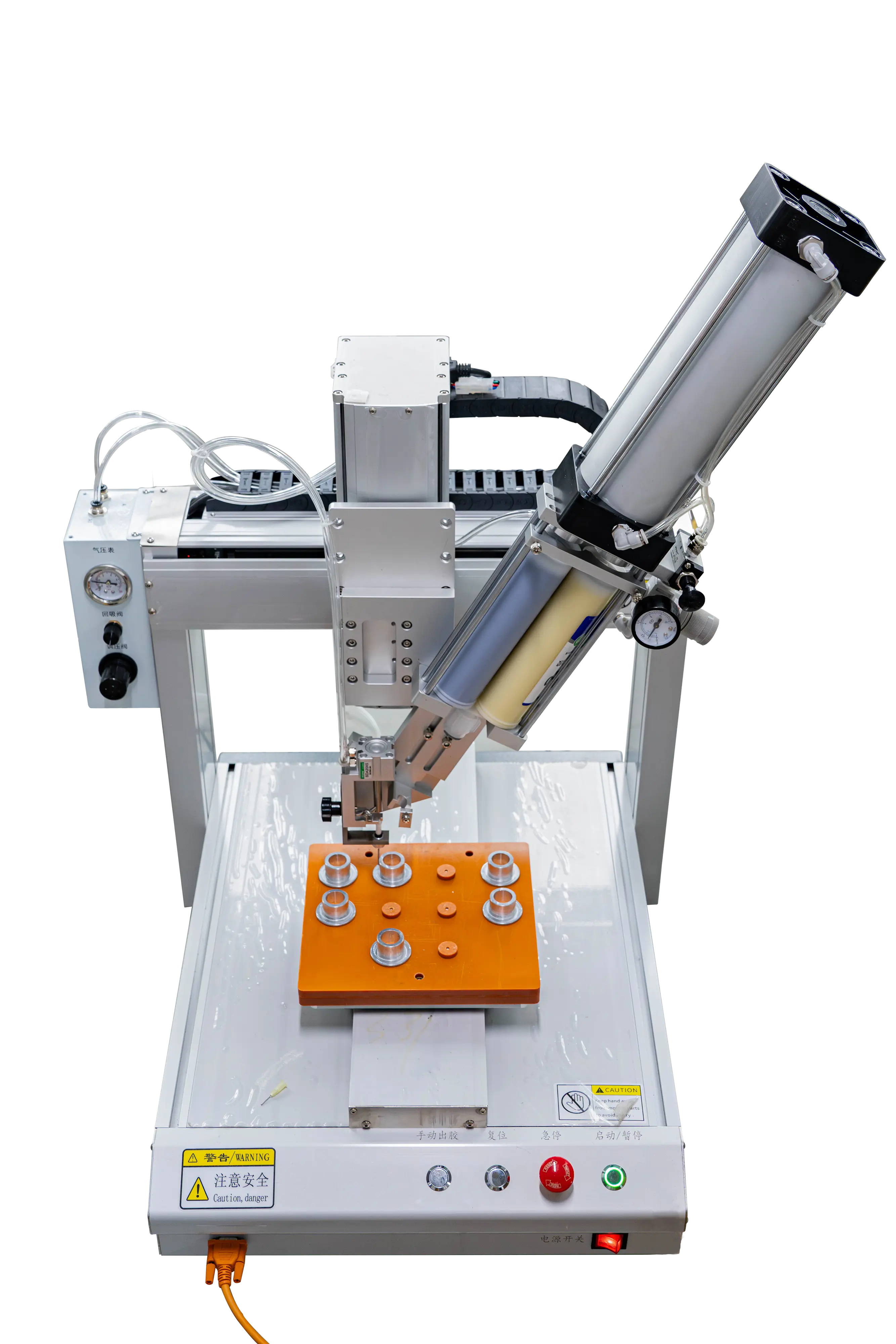

Selecting the appropriate epoxy dispensing machine is essential for achieving high productivity and quality. Key factors to consider include precision, speed, and durability. High-precision machines are crucial for intricate tasks, while faster machines can handle large-scale operations. Durability ensures longevity and reduces maintenance costs. For instance, CNC machines are ideal for complex projects requiring accuracy, whereas piston pumps are suitable for simpler, high-volume tasks. By choosing the right machine, you can significantly improve the efficiency and reliability of your epoxy dispensing process.

Pre-Dispensing Techniques for Optimal Results

Pre-dispensing techniques play a vital role in achieving consistent epoxy dispersion. Surface cleaning is the first step, ensuring a smooth substrate for even distribution. Using pressure sprayers or mechanical tools can remove contaminants effectively. Temperature control is another critical factor; adjusting the environment to the optimal temperature for the epoxy ensures better dispersion. Material compatibility is also crucial; selecting the right epoxy and substrate prevents premature cracking or delamination. Proper pre-dispensing sets the foundation for a successful epoxy application.

Calibration and Maintenance Tips

Regular calibration and maintenance are vital for maintaining machine efficiency. Calibration ensures the machine operates within specified parameters, preventing errors. Tools like calibration jigs and software can assist in this process. Maintenance involves checking for wear and tear, lubricating moving parts, and cleaning components. For example, replacing worn-out bearings or replacing worn belts can extend machine life. Regular maintenance not only enhances performance but also reduces downtime and operational costs.

Specific Tips for Various Dispensing Applications

Different applications require tailored approaches. Micro-dispensing, used in electronics, benefits from fine nozzles and precise control. Proper viscosity control and nozzle cleaning are essential to prevent clogs. Macro-dispensing, on the other hand, often uses gravity feed systems, requiring attention to pressure regulation to ensure smooth operation. Specialized dispensers, such as those with angled nozzles, are ideal for complex geometries. Understanding the specific needs of each application allows for optimized epoxy dispensing.

Case Study: Optimizing Epoxy Dispensing in Industrial Manufacturing

A company faced challenges with epoxy dispensing, leading to defective parts and increased waste. By upgrading to a precision CNC machine and implementing best practices in pre-dispensing and maintenance, they achieved a 30% reduction in defects and a 25% increase in production efficiency. This case study illustrates how adopting effective strategies can yield significant improvements in both quality and productivity.

Overcoming Common Challenges

Common challenges include misalignment, dripping, and uneven distribution. Misalignment can be addressed by precise setup and regular calibration. Dripping can be mitigated by ensuring correct pressure and nozzle alignment. Uneven distribution may require adjusting dispensing angles or using specialized tools. Proactive measures, such as preventive maintenance and regular inspections, can minimize these issues, ensuring a reliable dispensing process.

Continuous Improvement Through Data Analysis

Data analysis is a powerful tool for optimizing epoxy dispensing. Techniques like statistical process control (SPC) help monitor and improve performance by identifying trends and variations. Regularly collecting and analyzing data allows for proactive adjustments, ensuring the process remains efficient. By leveraging data-driven insights, manufacturers can continuously refine their practices, leading to ongoing improvements.

Finalizing Best Practices for Epoxy Dispensing

Efficient epoxy dispensing requires a combination of machine selection, proper pre-dispensing, routine maintenance, and a tailored approach to applications. By implementing these strategies, you can achieve consistent results and enhance productivity. Whether in electronics, construction, or manufacturing, adopting best practices ensures the highest quality and reliability in your epoxy dispensing operations. Elevate your process today and witness the benefits of optimized epoxy dispensing.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China