Efficient Epoxy Mixing and Dispensing: Machine Insights

Epoxy materials are a game-changer in industries ranging from aerospace to electronics, thanks to their exceptional strength and versatility. However, the process of mixing and dispensing these materials can be tricky. Traditional methods often fall short, leading to costly errors and delays. Efficient epoxy mixing and dispensing machines have emerged as game-changers, transforming production and improving quality. These modern machines are tailored to various applications, from aerospace engines to intricate electronics components. For instance, a single mix error in aerospace can have catastrophic consequences. By using advanced epoxy mixing and dispensing machines, industries can achieve higher standards of precision and efficiency.

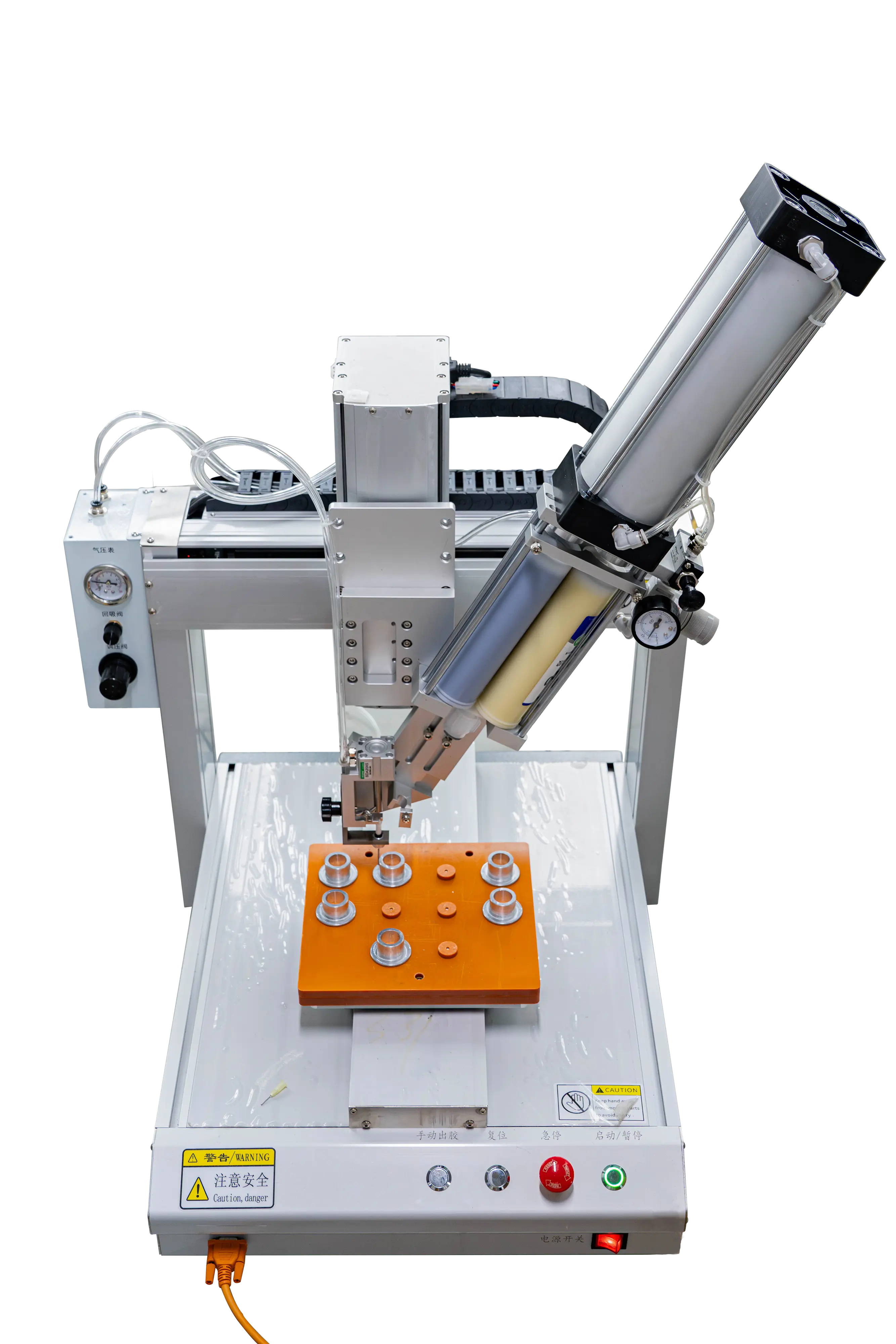

Understanding the Machines: Tools of the Trade

Epoxy mixing and dispensing machines are like precision tools, designed to handle the unique properties of epoxy resins. Lets break down the critical components:

- Mixers: These are the heart of the machine, responsible for combining epoxy components in the correct ratio. High-quality mixers ensure uniform mixing, essential for achieving the desired properties. For example, in the aerospace industry, high-performance mixers are used to mix engine components with precision. These mixers can handle a wide range of viscosities and ensure that the epoxy mixture is free from any lumps or inconsistencies.

- Nozzles: Precision dispensing is crucial for many applications. Nozzles come in different types, such as atomizers and impact nozzles, each designed for specific dispensing requirements. Atomizers are ideal for creating fine, even distributions, while impact nozzles provide a more concentrated flow, ideal for intricate designs. For instance, in electronics manufacturing, companies like Huawei use impact nozzles to apply precise amounts of epoxy, ensuring optimal performance and reliability. Atomizers, on the other hand, are more common in rapid prototyping and small-part production, where quick and effective mixing is essential.

- Control Systems: These systems manage the entire process, from mixing to dispensing, with precision and repeatability. Advanced control systems can automate the process, minimizing human error. For example, in the automotive industry, Ford Motor Company uses advanced control systems to manage the paint application process, ensuring consistent and uniform results across their assembly line.

Optimizing Epoxy Mixing for Precision and Quality

Achieving the perfect epoxy mixture is crucial for consistent results. Precise mixing ratios are essential to avoid contamination and ensure the epoxy performs optimally. Key factors that influence mixing include temperature control, speed, and the type of mixer used.

- Temperature Control: Temperature fluctuations can significantly affect the viscosity and cure time of epoxy. Maintaining consistent temperatures during mixing ensures uniform results. For example, in the aerospace industry, a single degree variance in temperature can lead to significant changes in the epoxys properties. Therefore, temperature control is critical for optimizing the mixing process.

- Mixing Techniques: Techniques like static and dynamic mixing can be used to achieve different outcomes. Static mixing involves placing a series of stators and rotors in the mixing chamber to create a uniform mix. Dynamic mixing uses rotating blades to create high-shear mixing, suitable for larger batches and more complex mixtures. For instance, in the automotive industry, dynamic mixing is used to achieve uniformity in paint formulations, ensuring a flawless finish on vehicles. In electronics, static mixing is often used in rapid prototyping and small-part production, leading to faster and more effective mixing.

Advanced Dispensing Controls and Applications

Dispensing precision is where the rubber meets the road. The range of nozzles and controls available today allows for highly precise dispensing, whether for small dots or intricate patterns. These controls can range from basic manual adjustments to fully automated systems.

- Types of Nozzles: Different nozzles are designed for various purposes. For example, atomizers create fine, even distributions, while impact nozzles provide a more concentrated flow. In the aerospace industry, Airbus uses atomizers to apply precise amounts of epoxy in engine production, ensuring optimal performance. Impact nozzles, on the other hand, are more common in electronics manufacturing, where they are used to apply epoxy to intricate components.

- Precision Controls: Modern systems allow for real-time adjustments to ensure precise dispenses. Automation can streamline the process, removing the risk of human error. For example, in the electronics industry, companies like Huawei use advanced dispensing systems to apply precise amounts of epoxy to intricate components, ensuring optimal performance and reliability.

Comparing Traditional Methods with Modern Epoxy Mixing and Dispensing Machines

Traditional methods, while effective, often fall short in speed and accuracy. Modern machines offer significant advantages, including faster production and higher quality. A cost analysis and return on investment (ROI) show that the transition to modern machinery can yield substantial benefits.

- Traditional Methods: Manual mixing and dispensing can be time-consuming and subject to human error. These methods are often used in small-scale or low-volume production settings. For example, in a small electronics factory, manual mixing can lead to inconsistencies in the epoxy application, affecting the overall quality of the product.

- Modern Machines: Automated systems can mix and dispense epoxies with high precision and consistency, significantly reducing errors and improving efficiency. For example, a PCB manufacturer that shifted to an automated epoxy dispensing system saw a 30% reduction in production time and a 20% improvement in first-pass yield. This transition not only improves efficiency but also enhances the quality of the final product.

Maintenance and Troubleshooting of Epoxy Mixing and Dispensing Machines

Regular maintenance is vital for ensuring the longevity and optimal performance of epoxy mixing and dispensing machines. Here are some best practices:

- Routine Inspections: Regularly check the condition of components, such as mixers and nozzles, for wear and tear. For example, in the aerospace industry, routine inspections help identify and address issues early, preventing costly downtime. A comprehensive maintenance program implemented by an aerospace company led to a 90% reduction in machine downtime, ensuring that machines operate at peak efficiency.

- Cleaning Procedures: Follow the manufacturers guidelines for cleaning and maintaining the machine to prevent contamination and ensure accuracy. For example, in the automotive industry, regular cleaning and maintenance of epoxy dispensing systems help maintain consistent performance and reliability.

- Fault Diagnosis: Common issues include clogged nozzles, misaligned components, and malfunctioning control systems. Regular maintenance can help identify and address these issues early. For instance, a company in the electronics industry implemented a comprehensive maintenance program, which led to a 90% reduction in machine downtime and significant cost savings.

Real-World Applications of Epoxy Mixing and Dispensing Machines

Real-world applications in aerospace, automotive, and electronics showcase the impact of epoxy machinery. These case studies highlight how modern solutions have improved efficiency and quality.

- Case Study 1: Aerospace Industry

In the aerospace industry, Airbus implemented automated epoxy dispensing systems in their engine production facilities. This transition not only reduced production time by 25% but also improved the quality of engine components, enhancing performance and safety. For example, the use of automated dispensing systems ensured consistent and uniform application of epoxy, leading to fewer defects and improved engine reliability.

- Case Study 2: Automotive Sector

Ford Motor Company adopted advanced epoxy mixing and dispensing machines in their paint production line. The implementation of these systems led to a 30% reduction in production time and a significant improvement in the uniformity and quality of painted surfaces. The use of advanced dispensing systems ensured consistent and precise application of epoxy paints, leading to a flawless finish on vehicles.

- Case Study 3: Electronic Manufacturing

Huawei transitioned to automated epoxy dispensing systems for their electronics assembly line. The transition not only improved the accuracy of component placement but also increased first-pass yield from 75% to 95%. For example, the use of advanced dispensing systems ensured precise application of epoxy to intricate components, leading to a significant improvement in the overall quality of the final product.

Future Trends and Innovations in Epoxy Mixing and Dispensing Technology

Emerging technologies and trends, such as IoT integration and advanced software controls, are set to revolutionize epoxy handling. Heres a preview of whats coming:

- IoT Integration: Machines can now be linked to IoT networks, allowing for real-time monitoring and data analysis. This enables predictive maintenance and improved efficiency. For example, an aerospace company integrated IoT into their epoxy dispensing systems, enabling real-time tracking of machine performance and predictive maintenance.

- Advanced Software Controls: New software solutions can optimize mixing and dispensing processes, providing real-time adjustments and better outcomes. For example, a company in the electronics industry implemented advanced software controls, which optimized the epoxy mixing process, leading to a 15% reduction in errors.

- Emerging Technologies: Look for advancements that integrate machine learning and AI to predict and prevent issues, providing an even higher level of automation and precision. For example, a leading electronics manufacturer is currently testing AI-driven systems that predict and prevent issues before they occur, leading to even greater efficiency and reliability.

The Critical Role of Epoxy Mixing and Dispensing Machines

Efficient epoxy mixing and dispensing are cornerstone processes in modern manufacturing. By adopting advanced machinery, industries can achieve higher standards of quality and productivity. Encouraging investment in these technologies is key to future success. As we move forward, the future of epoxy machinery looks promising, with continuous innovation driving improvements and efficiencies.

Invest in modern epoxy machinery to stay ahead in the competitive landscape. Whether you're in the aerospace, automotive, or electronics industry, the transition to advanced machinery can significantly enhance your operations. Embrace the power of modern epoxy mixing and dispensing machines to unlock unparalleled precision and efficiency.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China