Innovative Resin Dispensing Machine Accessories You Need

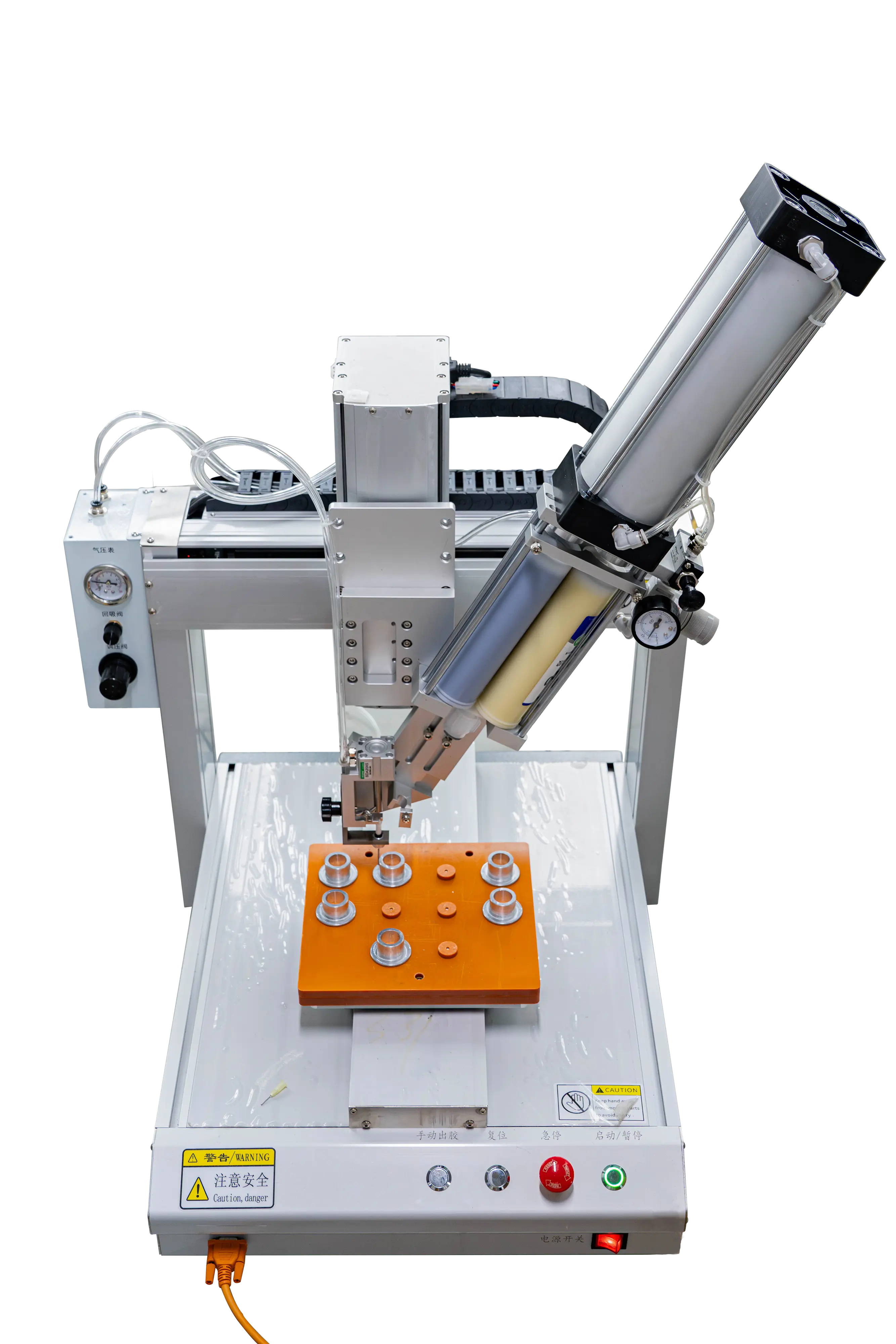

Resin dispensing machines have become a cornerstone in many industries, offering precise and efficient solutions for applying resin-based materials. These machines are designed to handle various types of resin, including thermoplastic and thermoset polymers, and are used to create everything from thick coatings to delicate finishes. However, as the complexity of modern resin applications increases, so do the demands on the tools and accessories that accompany these machines.

The evolution of resin dispensing machines has led to the development of innovative accessories that improve functionality, reduce waste, and increase productivity. These accessories are not just supplementary tools but integral components of the overall system, designed to work seamlessly with the machine to achieve optimal results. Whether youre working on a large-scale construction project or a small electronics assembly, the right accessories can make a significant difference in the quality and efficiency of your work.

Enhancing Precision with Adhesive Coating Heads

One of the most critical accessories for resin dispensing machines is the adhesive coating head. These specialized tools are designed to apply thin, precise coats of resin onto the surface being worked. Unlike traditional dispensers, which rely on gravity or pressure alone, adhesive coating heads use a combination of precision engineering and advanced materials to ensure even and consistent application of resin.

The benefits of using adhesive coating heads are numerous. First and foremost, these heads provide a higher level of precision, ensuring that the resin is applied in the exact shape and thickness required. This is particularly important in industries where even a small defect can compromise the integrity of the final product, such as in electronics manufacturing or aerospace.

In addition to their precision, adhesive coating heads are highly durable and resistant to wear and tear. They are designed to withstand the rigors of continuous use, even in demanding environments. Furthermore, these heads can be used with a variety of resin types, making them a versatile solution for different applications.

Another key advantage of adhesive coating heads is their ability to reduce waste. By ensuring that the resin is applied in the exact quantity and shape needed, these heads help to minimize excess material and improve overall efficiency. This is especially important in industries where material waste can be costly, such as in construction or automotive manufacturing.

Overall, adhesive coating heads are an essential accessory for anyone working with resin dispensing machines. They provide precision, durability, and efficiency, making them a valuable addition to your toolkit.

Streamlining Workflow with Multi-Head Dispensing Systems

As resin dispensing machines become more advanced, so do the systems that control them. Multi-head dispensing systems are one of the most innovative accessories that have emerged in recent years, offering a range of benefits for manufacturers and users alike. These systems allow multiple nozzles to dispense resin simultaneously, creating a more efficient and productive workflow.

One of the key advantages of multi-head systems is their ability to handle multiple tasks at once. For example, a single machine equipped with a multi-head system can dispense resin onto several parts or substrates at the same time, significantly reducing the time required to complete a job. This is particularly beneficial in industries where time is of the essence, such as in high-volume production environments.

In addition to their speed and efficiency, multi-head systems are also highly flexible. They can be configured to suit a wide range of applications, from small-scale projects to large-scale manufacturing operations. Whether youre working with thermoplastic resin or thermoset polymer, these systems are designed to handle it all with ease.

Another important feature of multi-head systems is their ability to integrate with other components of the production process. For example, they can be connected to CNC machines, robotic arms, or other automated systems, creating a seamless workflow that maximizes productivity and minimizes downtime.

Overall, multi-head dispensing systems are a game-changer for anyone working with resin dispensing machines. They offer speed, efficiency, and flexibility, making them a must-have accessory for modern manufacturers.

Ensuring Quality Control with Pressure and Flow Rate Monitors

Quality control is a critical aspect of any resin dispensing operation, and innovative accessories are playing a key role in ensuring that the final product meets the highest standards. Pressure and flow rate monitors are two of the most essential accessory systems that help maintain consistency and precision in the dispensing process.

Pressure monitors are designed to regulate the pressure of the resin being dispensed, ensuring that the right amount of material is applied to each surface. This is particularly important in industries where pressure variations can lead to defects or inconsistencies, such as in electronics manufacturing or aerospace.

Flow rate monitors, on the other hand, are used to control the speed at which the resin is dispensed. By adjusting the flow rate, these monitors can ensure that the resin is applied in the exact quantity and thickness needed, reducing waste and improving efficiency.

Together, pressure and flow rate monitors provide a comprehensive system for maintaining quality control in the dispensing process. They are highly versatile and can be used with a wide range of resin types and machine configurations, making them a valuable accessory for anyone working in this field.

Improving Operational Flexibility with Retractable Nozzles

Retractable nozzles are one of the most innovative accessories that have been developed in recent years, offering significant benefits for users of resin dispensing machines. These nozzles are designed to be fully retractable, allowing for easy and efficient cleaning, maintenance, and refilling of resin.

One of the key advantages of retractable nozzles is their ability to reduce downtime. Traditional nozzles often require manual cleaning and refilling, which can be time-consuming and labor-intensive. Retractable nozzles, on the other hand, are designed to be self-cleaning, minimizing the need for manual intervention. This makes them particularly useful in high-volume production environments, where efficiency and reliability are critical.

In addition to their cleaning and maintenance benefits, retractable nozzles are also highly versatile. They can be used with a wide range of resin types and machine configurations, making them a valuable accessory for anyone working in this field.

Another important feature of retractable nozzles is their ability to improve operator safety. By reducing the need for manual intervention, these nozzles can help to minimize the risk of accidents and injuries in the workshop or production environment.

Overall, retractable nozzles are a highly innovative accessory that offers significant benefits for users of resin dispensing machines. They improve efficiency, reduce downtime, and enhance safety, making them an essential addition to any workshop or production environment.

Enhancing Safety with Automated Dispensing Heads

Automated dispensing heads are one of the most advanced accessories that have been developed in recent years, offering a range of benefits for users of resin dispensing machines. These heads are designed to operate automatically, with minimal human intervention, making them highly efficient and reliable.

One of the key advantages of automated dispensing heads is their ability to reduce the risk of errors. Traditional dispensing heads often require manual adjustments and monitoring, which can be time-consuming and prone to human error. Automated heads, on the other hand, are designed to operate with a high degree of precision, reducing the risk of mistakes and ensuring consistent results.

In addition to their error-reduction benefits, automated dispensing heads are also highly durable and resistant to wear and tear. They are designed to withstand the rigors of continuous use, even in demanding environments, making them a reliable addition to any machine.

Another important feature of automated dispensing heads is their ability to integrate with other components of the production process. For example, they can be connected to CNC machines, robotic arms, or other automated systems, creating a seamless workflow that maximizes efficiency and productivity.

Overall, automated dispensing heads are a highly innovative accessory that offers significant benefits for users of resin dispensing machines. They enhance safety, reduce errors, and improve efficiency, making them an essential tool for anyone working in this field.

Embracing Innovation in Resin Dispensing Technology

As the world of resin dispensing machines continues to evolve, so do the accessories that complement them. From adhesive coating heads to multi-head dispensing systems, retractable nozzles to automated dispensing heads, innovative accessories are driving the industry forward and enabling users to achieve higher levels of precision, efficiency, and quality.

These accessories not only enhance the performance of resin dispensing machines but also improve the overall manufacturing process, reducing waste, minimizing downtime, and increasing productivity. Whether youre working in construction, automotive, electronics, or any other industry, the right accessories can make a significant difference in the quality and efficiency of your work.

In conclusion, embracing innovation in resin dispensing technology is essential for meeting the demands of modern manufacturing and achieving optimal results. By investing in the right accessories, you can ensure that your resin dispensing machine operates at its best and delivers the highest quality of output.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China