Smart Manufacturing: How Automatic Screw Feeders are Revolutionizing the Industry

Understanding Automatic Screw Feeders: A Necessity in Modern Assembly Lines

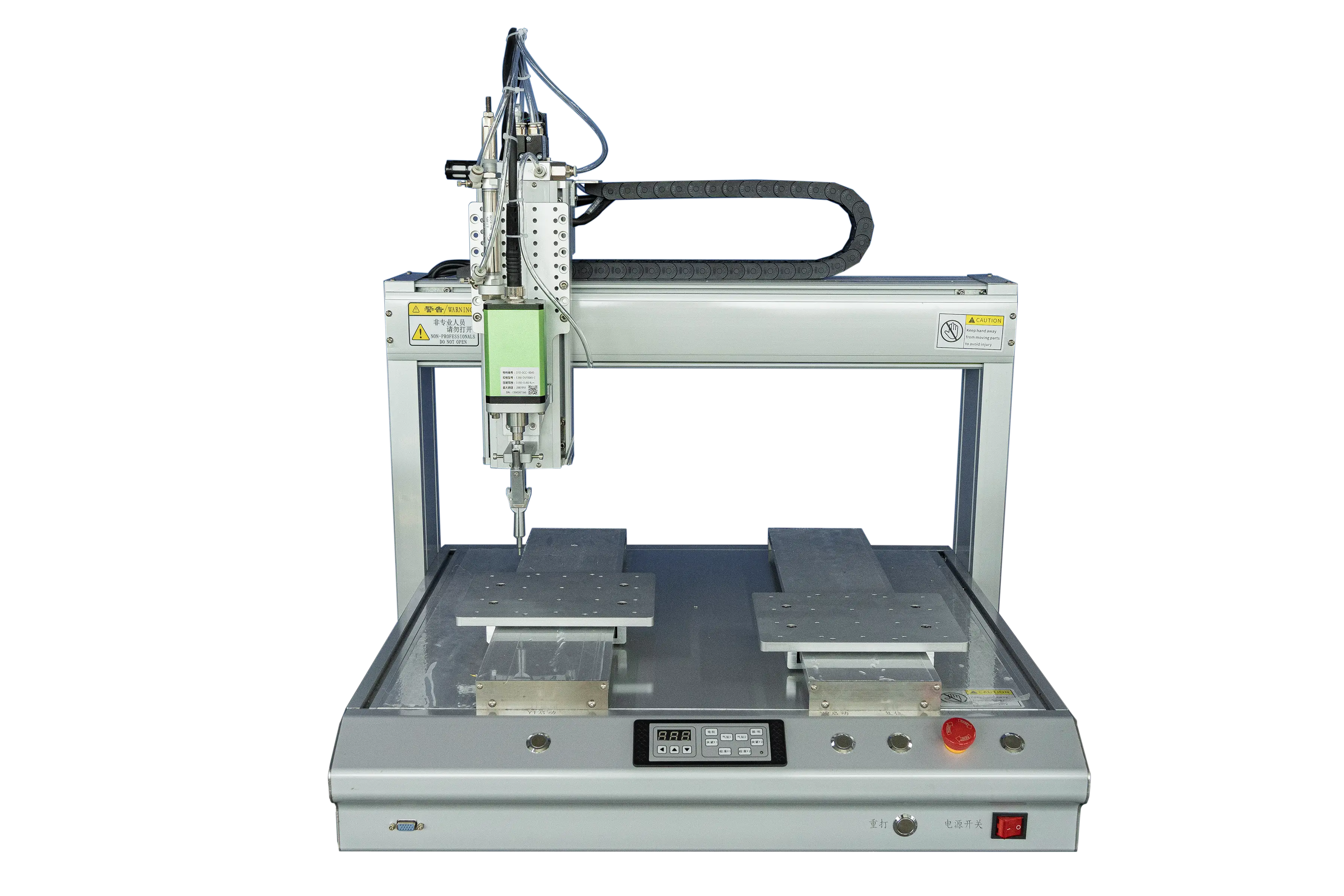

Automatic screw feeders are devices that automatically supply screws to production machinery, maintaining a consistent rate and reducing errors. These feeders are crucial for maintaining uniformity and speed in assembly lines, making them indispensable in modern manufacturing. They are equipped with sensors and control systems that adjust feeding rates in real-time, ensuring precise and efficient operations.

Imagine a scenario where a production line is running smoothly, with screws fed automatically and consistently. This level of precision not only boosts productivity but also minimizes errors and material waste. Screw feeders ensure that every screw is placed accurately, reducing the likelihood of defects and enhancing overall product quality.

Benefits of Automatic Screw Feeders: Boosting Productivity and Reducing Costs

Automatic screw feeders offer numerous benefits that significantly enhance manufacturing operations. Here are the key advantages:

- Increased Efficiency: By automating the screw-feeding process, these feeders reduce downtime and increase throughput. This ensures that production lines operate smoothly and efficiently, outputting more products in less time.

- Cost Savings: Automatic screw feeders reduce material waste, decrease labor costs, and improve machine utilization. Over time, these cost savings can substantially offset the initial investment.

For instance, a study conducted by a leading manufacturing firm found that implementing automatic screw feeders resulted in a 15% reduction in production time and a 20% increase in output. The reduction in material waste and labor costs further contributed to significant cost savings.

Consider a real-world example: In a high-volume electronics assembly plant, the implementation of automatic screw feeders led to a 25% reduction in production time. This not only increased the number of devices produced but also allowed the company to reallocate labor to other critical areas, further improving efficiency.

Implementing Automatic Screw Feeders: A Step-by-Step Guide

Implementing automatic screw feeders requires a well-planned approach. Heres a step-by-step guide to ensure a smooth integration:

1. Assessment:

- Identify Bottlenecks: Evaluate your production process to identify areas where screw feeding is a bottleneck.

- Screw Requirements: Determine which screw sizes and quantities require automatic feeding.

2. Selection:

- Feeding Capacity: Choose the most suitable automatic screw feeder based on your needs, including feeding capacity and compatibility with existing machinery.

- Technical Specifications: Ensure the feeder meets your specific technical requirements.

3. Installation and Setup:

- Installation Steps: Follow a step-by-step guide to install the screw feeder, ensuring it is connected to power and data sources.

- Calibration: Calibrate sensors and program the control system to ensure accurate feeding rates.

4. Maintenance and Troubleshooting:

- Maintenance Schedule: Establish a maintenance schedule to address potential issues early.

- Regular Testing: Employ regular testing and checks to ensure the system operates efficiently.

By following these guidelines, manufacturers can integrate automatic screw feeders seamlessly into their operations, enhancing efficiency and reducing costs.

Real-World Examples of Successful Integration

Several industries have successfully integrated automatic screw feeders, achieving notable improvements:

1. Automotive Industry:

- A manufacturer reduced production time by 20% and increased output by 15% after implementing automatic screw feeders. The consistent feeding rate led to fewer defective parts and lower scrap rates. Additionally, the company saw a 30% reduction in machine downtime.

2. Precision Machinery Industry:

- A company faced issues with inconsistent screw sizes and frequent downtime. After adopting automatic screw feeders, production time was reduced by 30%, and throughput increased by 25%. The feeders handled multiple screw sizes seamlessly, enhancing efficiency.

These case studies demonstrate the transformative impact of automatic screw feeders on manufacturing processes.

Comparative Analysis: Traditional Methods vs. Automatic Screw Feeders

Traditional screw-feeding methods, such as manual and semi-automatic systems, suffer from inconsistencies and inefficiencies:

- Manual Feeding: Operators manually insert screws, leading to variability in screw sizes and feeding rates.

- Semi-Automatic Systems: These systems require more human intervention and can still result in errors and waste.

In contrast, automatic screw feeders:

- Precise and Consistent Feeding: Provide precise and consistent feeding, minimizing errors.

- Wide Range of Screw Sizes: Handle a wide range of screw sizes seamlessly.

- Reduced Maintenance: Require less maintenance and are more reliable.

By adopting automatic screw feeders, manufacturers can achieve greater precision and efficiency, setting new standards in the industry.

Future Trends and Innovations in Screw Feeding Technology

The future of screw feeding is being shaped by emerging trends and innovations, including:

- Smart Sensors: Embedded sensors provide real-time data, enabling on-the-fly adjustments.

- Predictive Maintenance: Algorithms predict potential issues, minimizing downtime.

- IoT Integration: Real-time monitoring and control from remote locations enhance flexibility and scalability.

- AI Optimization: AI analyzes production data to identify the most efficient feeding patterns.

These advancements promise even greater efficiency and reliability in manufacturing processes.

Embracing the Automated Future of Manufacturing

Automatic screw feeders are revolutionizing smart manufacturing by enhancing efficiency, reducing costs, and improving overall productivity. By adopting these technologies, manufacturers can set themselves apart in a competitive market. The future of manufacturing is increasingly automated and efficient.

To make a move, start by evaluating your current processes and identifying areas where automatic screw feeders can add value. Consider the benefits of precision and efficiency, and explore the various options available. Take the first step today to boost your operations and stay ahead in the industry.

Stay ahead of the curve and embrace the automated future of manufacturing.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China