Why You Need to Upgrade to an AB Glue Dispenser for Precision Work

In today's competitive manufacturing landscape, precision is the cornerstone of quality. Every minute, manufacturers lose significant time and resources to achieve that precision. Why? Because traditional glue application methods just aren't precise enough. They risk errors, waste, and subpar products. Enter the AB Glue Dispensera game-changer designed to revolutionize your glue application process.

The Significance of Precision in Adhesive Applications

Precision isn't just about making things look neat; it's a hallmark of quality craftsmanship. In manufacturing, a slight variation in glue application can mean the difference between a flawless product and a defective one. Imagine the implications: wasted materials, delayed production, and a tarnished reputation.

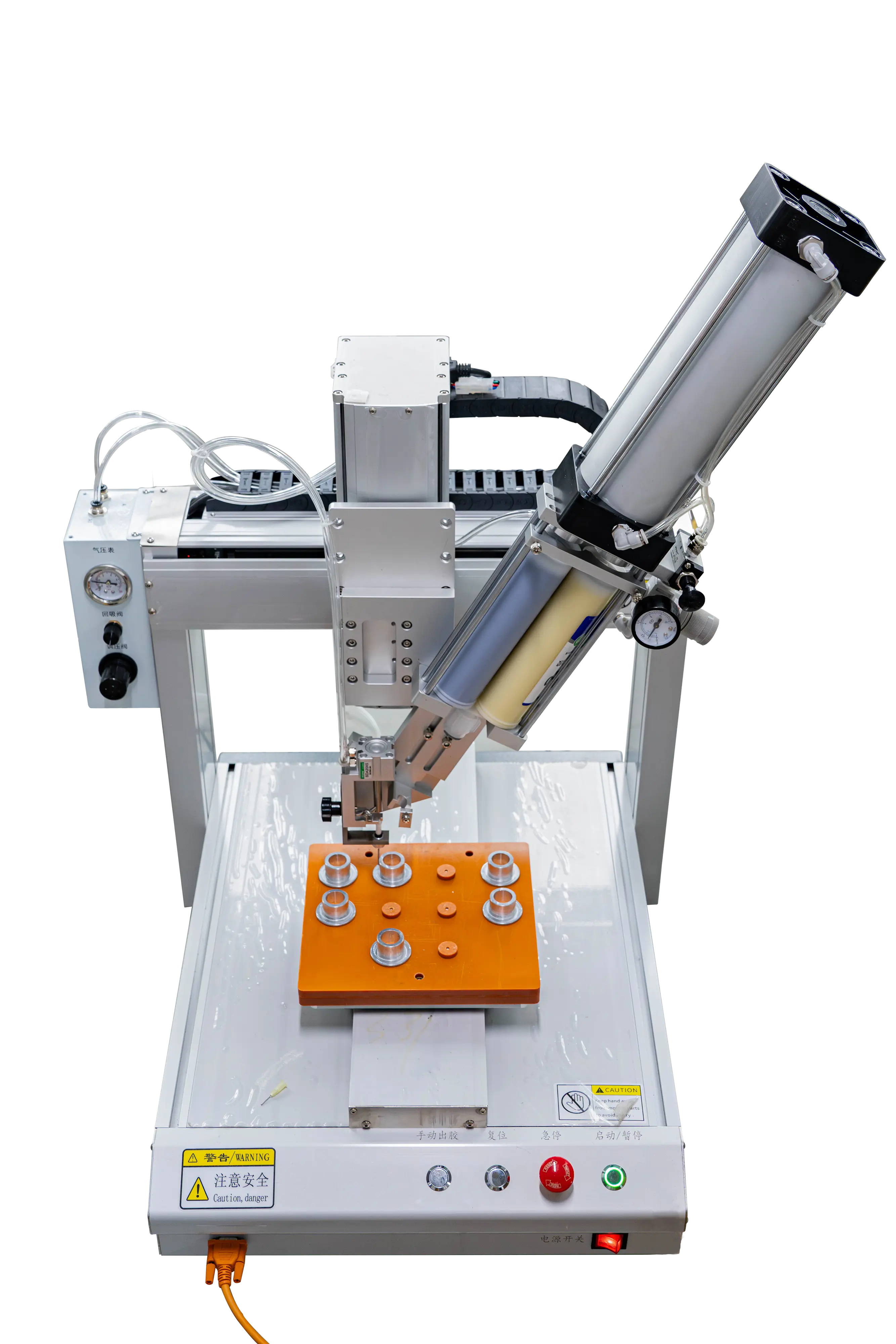

The AB Glue Dispenser is your solution. This advanced tool offers unparalleled precision, consistency, and efficiency. It's not just another glue container; it's a precision engineering marvel. With features like digital control, temperature regulation, and UV-curing technology, it ensures that every drop of glue is applied perfectly.

Understanding AB Glue Dispensers: Features and Benefits

The AB Glue Dispenser is equipped with several innovative features that set it apart from traditional methods:

- Digital Dispensing Technology: The AB Glue Dispenser uses sensors and algorithms to measure and dispense glue with pinpoint accuracy. No more siphoning glue by hand, which can lead to uneven application.

- Temperature Regulation: AB Glue Dispensers can control the temperature of the glue, ensuring it adheres properly and cures correctly. This is crucial for sensitive materials that require specific temperature conditions.

- UV-Curing Technology: Many AB Glue Dispensers come equipped with UV curing technology, which ensures the glue dries without smudging or warping. This is particularly beneficial for high-precision applications.

- Automated Control Systems: These systems allow for 24/7 operation, making them ideal for automated production lines. They can even adjust to the specific needs of different batches or products.

These features combined offer a range of benefits, including reduced waste, improved product quality, and streamlined workflows.

Comparison with Traditional Glue Application Methods

Traditional methods like squeeze tubes or brush applicators have their place, but they fall short when precision is key. Squeeze tubes require manual squeezing, leading to inconsistent amounts of glue. Brushes are slow, prone to smudging, and require constant adjustment.

In contrast, the AB Glue Dispenser offers:

- Precision: Each application is consistent, reducing waste.

- Speed: The dispenser operates automatically, saving time.

- Efficiency: It requires less glue per application, reducing material waste.

Real-World Examples of AB Glue Dispenser Usage

Imagine a manufacturing plant that upgraded its glue application to an AB Glue Dispenser. Previously, manual applications led to 5% waste. With the AB Dispenser, waste dropped by 10%. The plant also noticed a 15% improvement in product quality, with fewer defects due to precise glue application.

Another example: a packaging company that implemented an AB Glue Dispenser for sealing products. The dispenser ensured even pressure, resulting in 95% accurate seals. This not only reduced material waste but also improved delivery times, enhancing customer satisfaction.

Technical Advantages of AB Glue Dispensers

The AB Glue Dispenser boasts several technical advantages that set it apart from traditional tools. Its digital control systems allow for real-time monitoring and adjustments, ensuring optimal glue application. The temperature regulation feature is particularly innovative, as it prevents glue from smudging or drying incorrectly, which is a common issue in high-precision applications.

UV-curing technology ensures that glue cures cleanly, without residues that could affect product quality. This is especially beneficial for delicate materials used in industries like electronics or medical devices.

Cost-Benefit Analysis: Justifying the Investment

Investing in an AB Glue Dispenser may seem expensive, but the long-term benefits justify it. Initial costs include the purchase of the dispenser and any necessary setup or training. However, the savings come in the form of reduced waste, increased productivity, and improved product quality.

For example, a factory that upgraded its glue application saved $50,000 annually in waste alone. With proper training, operators can maximize efficiency, leading to even greater savings. The initial investment is a worthwhile extravagance for anyone serious about precision.

Future Trends in Precision Adhesive Application

The future of precision adhesive application is bright and evolving. With the advent of Industry 4.0 and smart manufacturing technologies, AB Glue Dispensers are set to play an even more significant role. Innovations like IoT integration will allow for real-time monitoring and adjustments, enhancing performance even further.

New technologies like AI-driven control systems will optimize glue dispensing based on production needs, reducing downtime and improving efficiency. Advanced material handling capabilities will enable the dispenser to work seamlessly with automated production lines, increasing throughput and precision.

Emphasizing the Value of Precision in Adhesive Applications

In conclusion, precision is essential in every aspect of manufacturing, from glue application to packaging. The AB Glue Dispenser offers a new level of precision, consistency, and efficiency that traditional methods simply can't match.

By investing in an AB Glue Dispenser, you're not just improving your production processes; you're enhancing the quality of your products, reducing waste, and staying ahead in a competitive market. The future of precision adhesive application lies with tools like the AB Glue Dispenser, and your factory is better for it.

Consider this upgrade: your investment in precision could be the difference between success and failure. Don't miss out on this opportunity to revolutionize your glue application with an AB Glue Dispenser. Start your journey towards precision today.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China