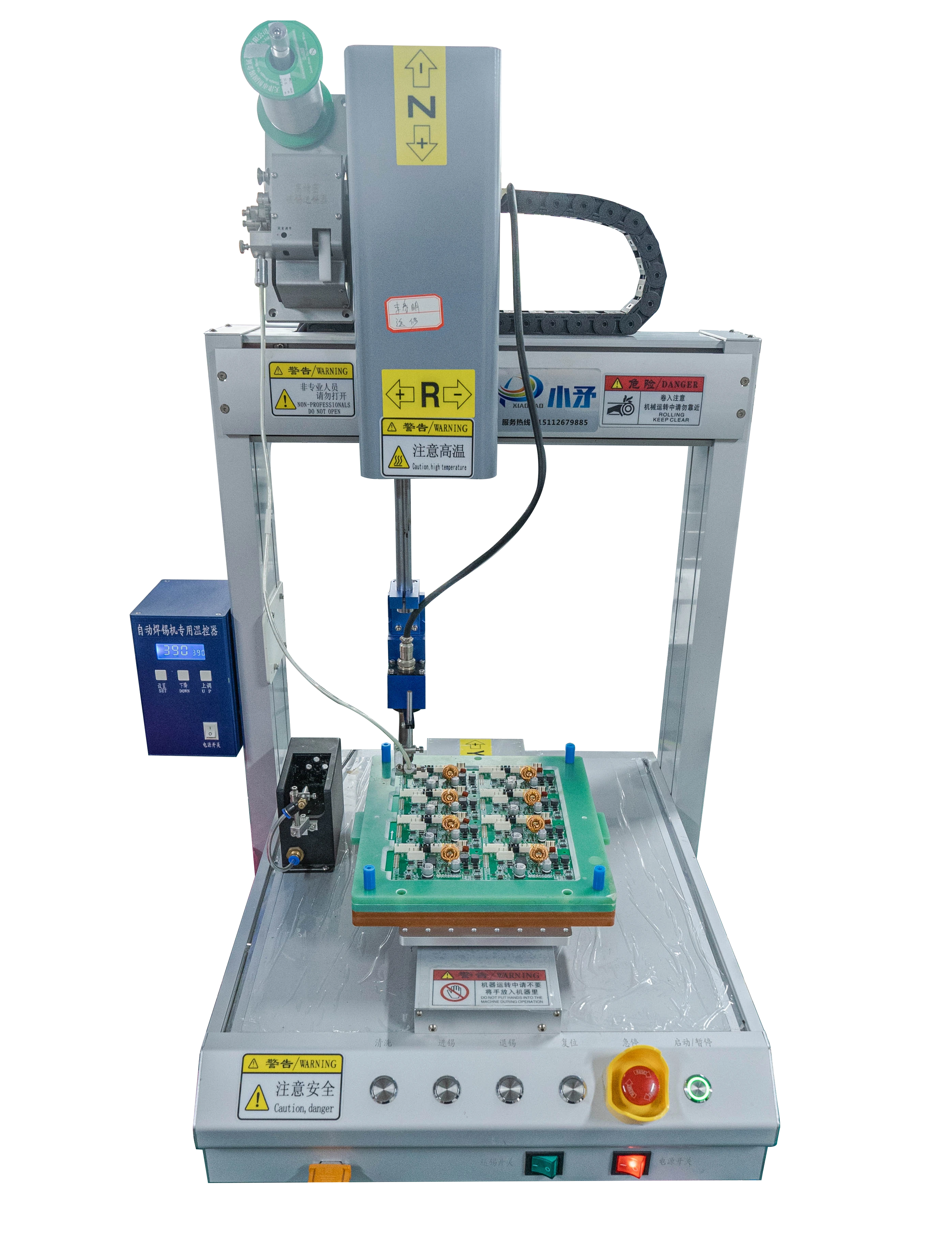

Single-station blue soldering iron tip soldering machine

2.24-hour global one-to-one efficient service.

3.Strong manufacturing, professional customization, quality assurance.

4.Have ISO, TUV and other international quality certifications.

5.Fast delivery, professional transportation.

6.On-site installation, simple and efficient.

Service:

Design and customize models, various styles, strong structure, support teaching, convenient transportation

Origin:

Shenzhen, Guangdong, China

Brand name:

Xiaomao Automation

More Choices

Model | ||

Working range X/Y/Z (mm) | 300*300*100/500*300*300*100 Customizable stroke | |

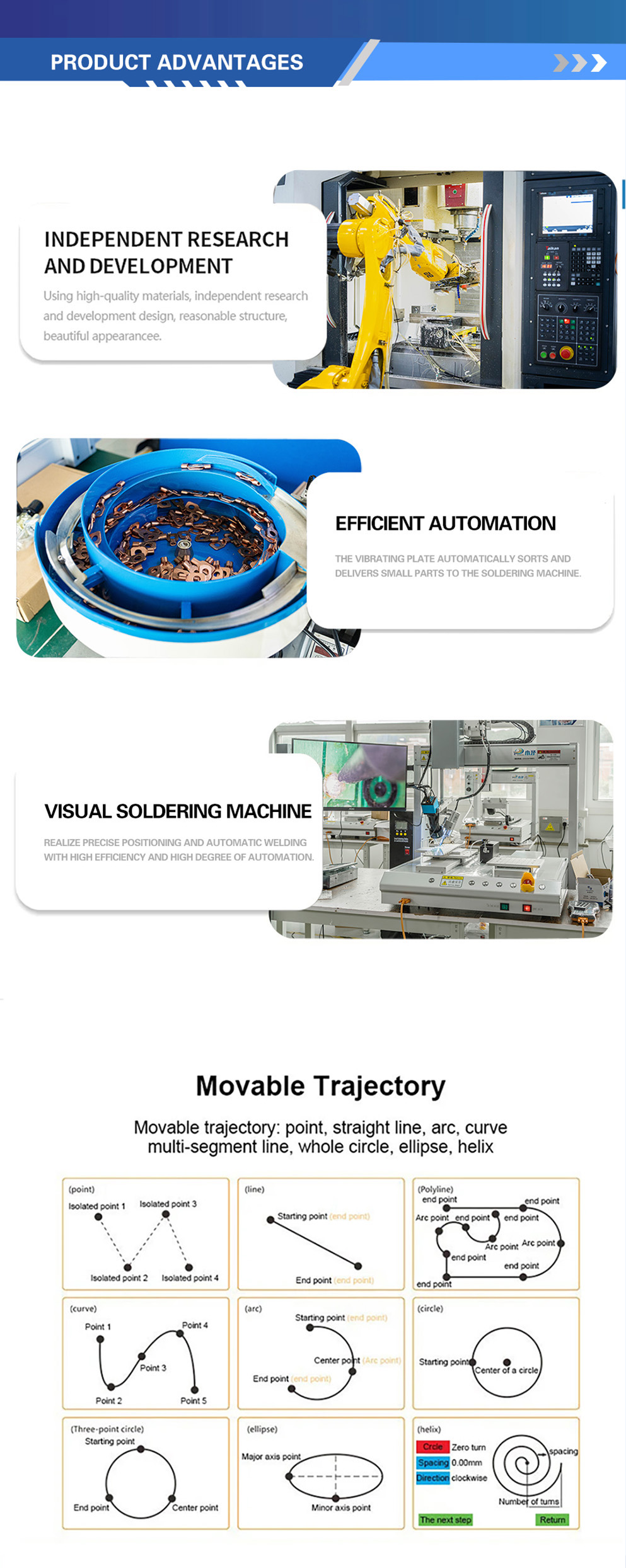

Programming method | Teaching programming or graphic import | |

Temperature control system | German Wilo/high frequency | |

Heating core | German Wilo/high frequency | |

Maximum load(kilogram) | 10 | |

Repeat accuracy(mm/Axis) | ±0.02 | |

Temperature error(℃) | ±2 | |

Working environment(℃) | Humidity | 20-90% |

temperature | 0-40 | |

Weight (kg) | 68 | |

Transmission mode | Taiwan Hiwin guide rail (slider) | |

Operating system | LCD panel/handheld programmer | |

Transmission mode | Guide rail | Taiwan Hiwin screw rod |

Belt | Italy Elate synchronous belt | |

Main selling point | easy to operate | |

Program storage capacity | 999 parameter files (65,535 points per file) | |

Motion mode | three-axis point-to-point, continuous straight line | |

Voltage | 110V~220V | |

Maximum speed (mm/s) | 500 | |

Marketing type | Ordinary product | |

Showroom location | Germany | |

Health condition | New | |

Warranty | 1 year | |

Core component warranty | 1 year | |

Mechanical test report | Provided | |

Video shipment inspection | Provided | |

Origin | Guangdong, China | |

Core components | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | |

Application | Industrial | |

Applicable products

| Circuit boards and components for mobile phones, computers, and other consumer electronics; ECUs, sensors, and dashboard components in the automotive electronics field; precision equipment modules such as monitors, blood glucose meters, and blood pressure monitors in medical electronics; circuit boards and interface components for communication equipment; control boards and small components for home appliances; and various electronic manufacturing products that require soldering, such as driver boards for LED lighting fixtures and light strip connection points | |

Applicable industries | hotels, clothing stores, building materials stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, restaurants, home use, retail, food stores, printing shops, construction projects, energy and mining, food and beverage stores, advertising companies, etc | |

FAQ

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China