Automating Your Screw Operations: Best Practices for Success

What is an Automatic Screw System?

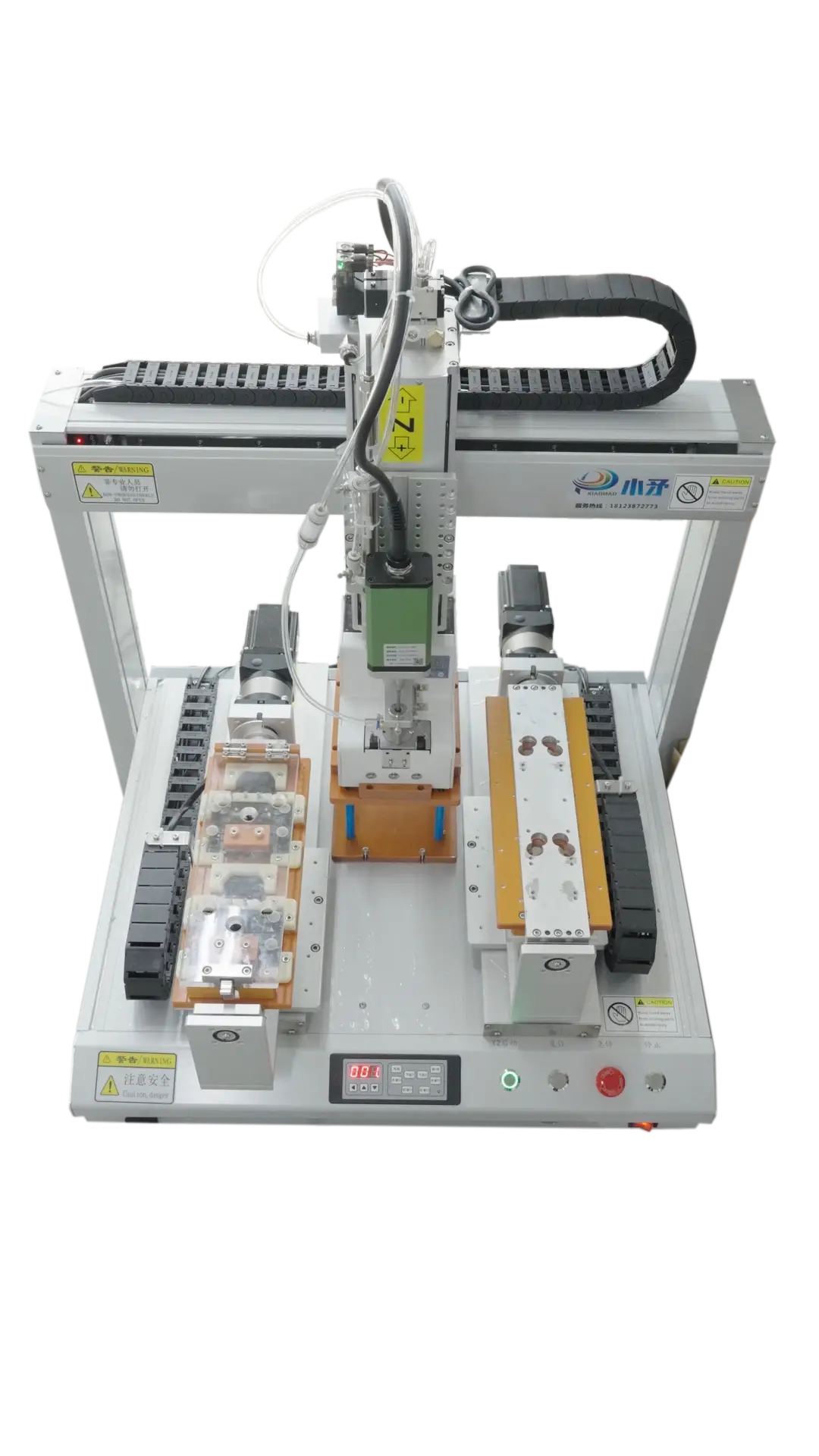

An automatic screw system is a technological advancement designed to replace or enhance traditional screw operations. It operates with minimal human intervention, often guided by sensors, software, and precise control mechanisms. The system can feed screws into machinery, tighten them, and even detect defects, ensuring high-quality output. There are various types of automatic screw systems, each tailored to different screw sizes and applications. For instance, linear feeders and robotic screw systems are commonly used in high-volume production lines. Comparing automatic systems with manual operations highlights their efficiency, reliability, and precision, making them an attractive solution for manufacturers.

Assessing Your Needs for an Automatic Screw System

Before transitioning to an automatic screw system, its essential to evaluate whether such a move is warranted. Factors to consider include production volume, the complexity of the screw operation, and the desired level of quality control. High-volume production lines, for example, can benefit significantly from automated systems, as they reduce the risk of human error and speed up the process. However, smaller operations may find that manual systems are sufficient, especially if they prioritize flexibility and adaptability. Conducting a cost-benefit analysis will help determine the return on investment for upgrading to an automatic system.

Choosing the Right Automatic Screw System

Selecting the appropriate automatic screw system involves evaluating its performance characteristics, reliability, and adaptability to your specific needs. Key considerations include precision, speed, and maintenance requirements. For example, a linear feeder may be ideal for smaller batches, while a robotic screw system is better suited for high-volume, complex operations. Its also important to assess the systems compatibility with existing machinery and control systems. Reading reviews and consulting with industry experts can provide valuable insights, ensuring that the chosen system aligns with your operational goals.

Implementing an Automatic Screw System in Your Operations

Implementing an automatic screw system requires careful planning and execution. The process begins with evaluating the production floor and machinery to determine where an automatic system can provide the most value. Procurement and installation must be carried out with precision, ensuring that the system integrates seamlessly with other equipment. Additionally, training staff is crucial, as they will need to operate and troubleshoot the system effectively. Common challenges include space constraints and the need for retooling, but with proper planning, these issues can be mitigated.

Maintaining and Optimizing Your Automatic Screw System

Maintenance is a critical aspect of ensuring the longevity and efficiency of an automatic screw system. Regular checks and cleaning of sensors and feeders are essential to prevent malfunctions. Calibration and troubleshooting should be approached systematically to identify and resolve issues promptly. Additionally, optimizing the systems performance by adjusting settings and monitoring its operation can lead to improved productivity. By prioritizing maintenance and continuous improvement, manufacturers can maximize the benefits of their automatic screw systems.

Successful Integrations of Automatic Screw Systems

Real-world examples of successful automatic screw system integrations provide valuable lessons and insights. For instance, a manufacturing facility that upgraded its screw operation to an automatic system saw a 30% reduction in defects and a 25% increase in production speed. Another company that implemented a robotic screw system reported a 40% improvement in throughput. These case studies highlight the potential for automation to drive significant operational improvements, but they also emphasize the importance of selecting the right system and following best practices during implementation.

Comparing Automatic Screw Systems with Other Automation Technologies

While automatic screw systems are highly effective, they may not always be the best solution for every manufacturing task. Comparing automatic screw systems with other automation technologies, such as robotic arms and vision systems, can provide a clearer picture of their respective strengths and limitations. Robotic arms, for example, excel in pick-and-place operations, while vision systems are excellent for quality control. Understanding these differences can help manufacturers choose the most appropriate automation solution for their specific needs.

Future Trends in Automatic Screw Technology

The future of screw operations is poised for significant advancements, with technologies like AI and IoT expected to play a key role. AI-driven systems can analyze production data in real-time, identifying inefficiencies and optimizing operations. IoT connectivity will enable manufacturers to monitor and control screw systems remotely, enhancing flexibility and scalability. These innovations promise to further elevate the efficiency and precision of screw operations, setting new standards for manufacturing excellence.

Embracing the Future of Screw Operations

As automation continues to transform the manufacturing industry, screw operations are no exception. By embracing automation, manufacturers can achieve higher levels of efficiency, consistency, and quality. Whether implementing a manual system, upgrading to an automatic system, or exploring emerging technologies, the key is to choose the solution that best fits your operational needs. Take the opportunity to learn from case studies, stay informed about industry trends, and consider how automation can enhance your screw operations. Embrace the future, and let technology drive your manufacturing success.

Feel free to reach out if you need further assistance or want to share your own experiences with automation in screw operations.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China