Epoxy Dispensing for DIY Projects: What to Know

Have you ever wished your DIY projects had a professional finish without the hefty price tag? Epoxy dispensing is no longer just for industrial settings; it can transform everyday projects into masterpieces. With the right tools and techniques, you can achieve flawless surfaces and intricate designs. This comprehensive guide will show you how to master epoxy dispensing for all your DIY projects.

Understanding the Basics: Types of Systems

Epoxy dispensing systems come in a variety of forms, each tailored to different project requirements. Lets dive into the main types and their unique advantages.

1. Manual Systems

- Description: The most basic and cost-effective options, manual systems require you to mix the epoxy by hand and dispense it using a syringe or a bottle with a nozzle.

- Ideal for: Small-scale projects where precision isnt a critical factor, such as decorative wood pieces, custom furniture legs, and minor repairs.

- Example: Crafting a DIY bookshelf with intricate carvings requires precise lines and shapes, which a manual system can achieve effectively.

2. Semi-Automated Systems

- Description: These systems offer touch-sensitive control, allowing for more precise dispensing. They often come with digital displays for monitoring the process.

- Ideal for: Medium-scale projects where precise control is necessary, such as countertops, decorative tiles, and small furniture pieces.

- Example: Creating a custom countertop with seamless edges, where even the tiniest deviation can affect the final look. A semi-automated system ensures every line is perfect.

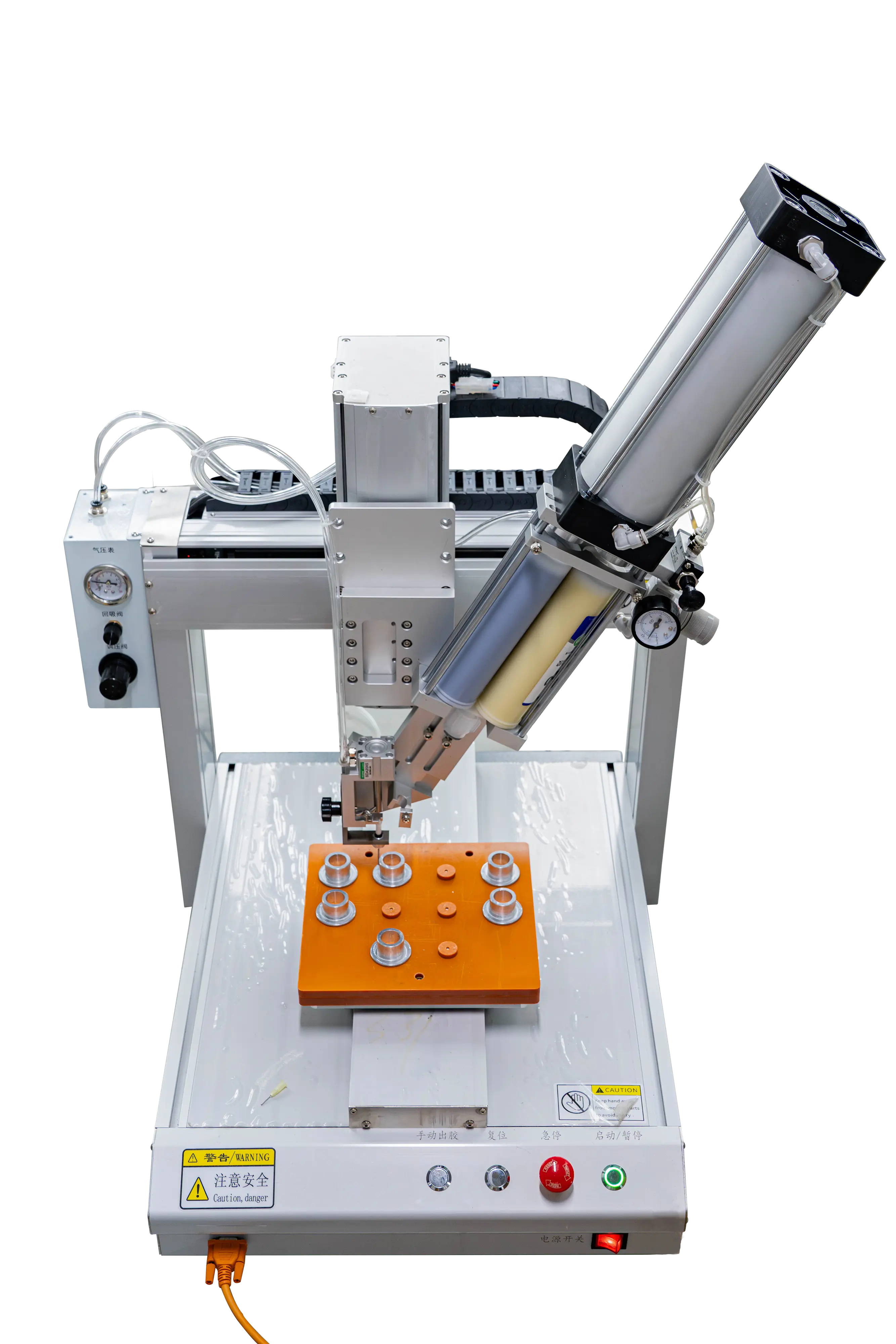

3. Fully Automated Systems

- Description: These high-tech systems use robotics for precise and consistent dispensing. They are ideal for large-scale projects with intricate designs.

- Ideal for: Large-scale projects such as flooring, boat hulls, and automotive body repairs.

- Example: Repainting a large boat hull requires uniform application across a vast surface, which is best achieved with a fully automated system. Every inch is evenly coated, ensuring a flawless finish.

Choosing the Right Tool: Factors to Consider

Selecting the right epoxy dispensing tool is a crucial step in achieving top-notch results. Here are the key factors to consider:

- Precision Requirements: High precision is critical for intricate designs. Semi-automated and fully automated systems offer the best control.

- Budget: Manual systems are more budget-friendly, while semi-automated and fully automated systems cost more but offer significant advantages.

- Project Scale: Small-scale projects benefit from manual or semi-automated systems, while large-scale projects may require fully automated systems.

- Material Compatibility: Some systems work better with specific types of epoxy. Ensure the tool is compatible with your chosen material.

Some essential features to look for include:

- High-Quality Nozzles: These ensure consistent and precise application.

- Control Software: Advanced software can help you monitor and adjust the dispense rate.

- Compatibility: Choose a system that is compatible with your epoxy type.

Practical Tips: A Step-by-Step Approach

Mastering epoxy dispensing involves more than just selecting the right tool. Heres a step-by-step guide to help you set up and execute your project perfectly:

1. Selection of Epoxy

- Choose the Right Epoxy: Select the right epoxy based on your project requirements. Consider factors like curing time, adhesion, and hardness.

2. Calibration

- Proper Calibration: Follow the manufacturer's instructions to set up your system accurately. This ensures consistent and precise results.

3. Application Process

- Surface Preparation: Start by priming the surface you will be working on. This ensures a smooth base and enhances adhesion.

- Mixing: Mix the epoxy according to the manufacturer's instructions. Use the appropriate nozzles for your project.

- Dispensing: Begin dispensing from the reference point and work your way out. Ensure even coverage to avoid pooling or uneven thickness.

- Curing: Allow the epoxy to cure according to the specified time. Ensure thorough drying before the next step.

Real-World Applications: Illustrating Success

Lets look at some real-world examples of successful DIY projects that highlight the benefits of proper epoxy dispensing.

1. Custom Countertop

- Project: Creating a custom countertop with intricate designs.

- Tools Used: Semi-automated system.

- Outcome: The result was a professionally finished countertop with seamless edges and intricate designs. The semi-automated system ensured precise lines and smooth transitions.

2. DIY Bookshelf

- Project: Crafting a bookshelf with intricate carvings and designs.

- Tools Used: Manual system.

- Outcome: The DIY bookshelf was flawless, with precise carvings and a polished finish. The manual system allowed for meticulous control and attention to detail.

Comparative Analysis: Epoxy Dispensing vs. Traditional Methods

Epoxy dispensing stands out from traditional methods due to its precision and efficiency. Heres a detailed comparison:

- Epoxy Dispensing

- Advantages:

- Offers precise and consistent results.

- Reduces waste and is faster.

- Ensures uniform application.

- Disadvantages:

- Initial investment can be high.

- Requires training and setup.

- Traditional Methods (Manual Pouring)

- Advantages:

- Low initial cost.

- straightforward to operate.

- Disadvantages:

- Less precise.

- More time-consuming.

- Prone to human error.

Looking Ahead: Emerging Trends in Epoxy Dispensing

The future of epoxy dispensing is exciting, driven by technological advancements. Here are some emerging trends:

1. AI-Driven Systems: These systems use artificial intelligence to improve accuracy and efficiency. For example, an AI system can predict and correct defects in real-time, ensuring perfect results.

2. Innovative Nozzles: New nozzle designs offer greater precision and versatility. For instance, textured nozzles can create unique patterns and effects, such as a distinctive stone-like texture.

3. Sustainability: Epoxy manufacturers are developing more eco-friendly options, reducing the environmental impact of your projects. These eco-friendly epoxies can be used on surfaces without harmful chemicals.

Embracing Epoxy Dispensing for Your Next DIY Project

Epoxy dispensing is a powerful tool that can elevate your DIY projects to the next level. By understanding the basics, choosing the right tool, and applying best practices, you can achieve professional results. With the right guidance and resources, you can transform your next project into a masterpiece. Embrace epoxy dispensing and take your DIY skills to new heights today.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China