Improving Precision and Efficiency with Epoxy Resin Dispensing Machines

Improving Precision and Efficiency with Epoxy Resin Dispensing Machines: A Comprehensive Guide

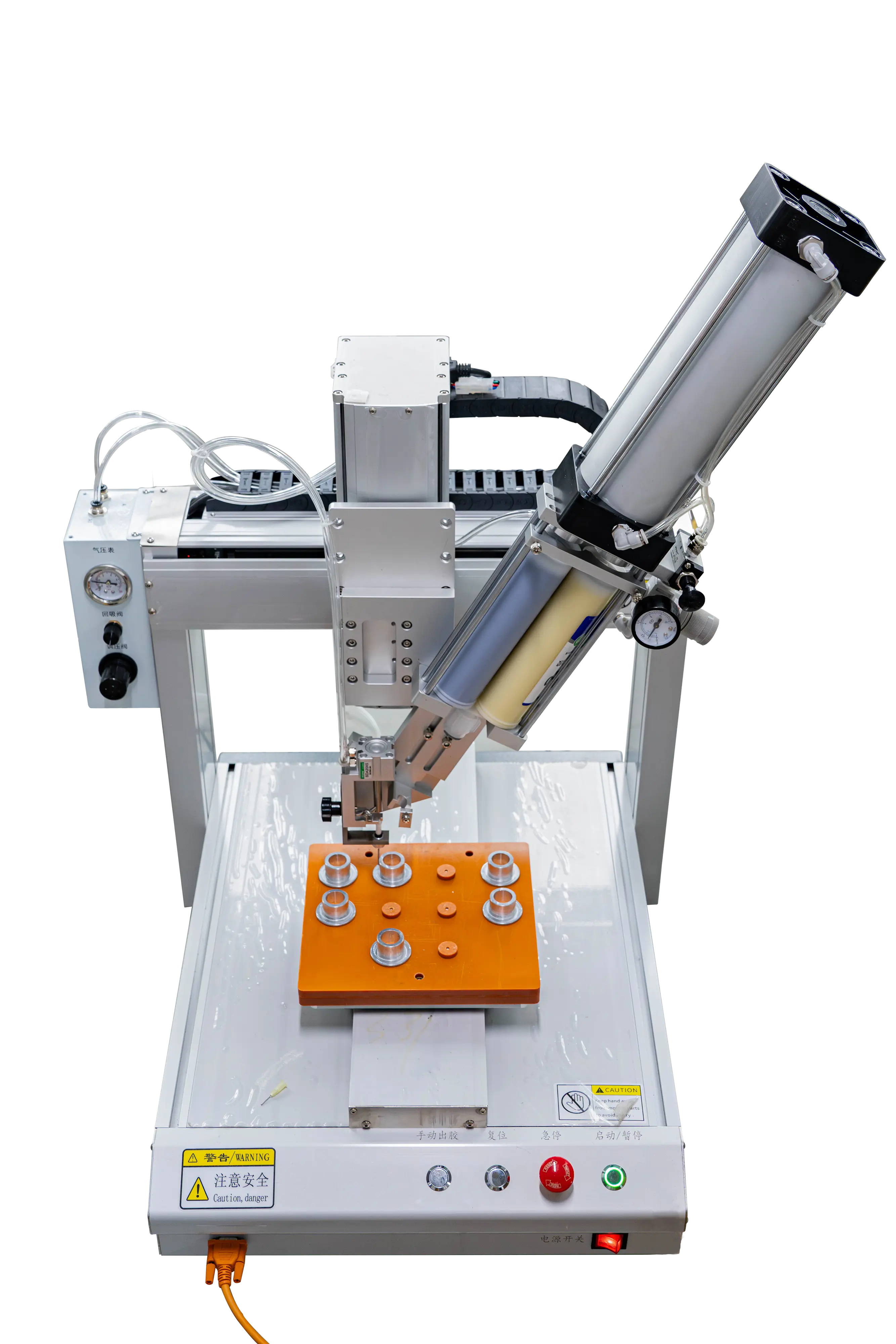

Epoxy resin is an essential material in various industrial applications, from electronics to aerospace, prized for its strong adhesion and durability. However, the process of applying epoxy resins can be challenging, requiring precision to ensure optimal results. Enter epoxy resin dispensing machines, tools designed to enhance accuracy and efficiency. This guide explores the importance of these machines, how they work, their advantages, and key considerations for selection and implementation.

!

How Epoxy Resin Dispensing Machines Work

Epoxy resin dispensing machines are designed to deliver precise amounts of resin quickly, minimizing waste and saving time. They operate using two primary methods: piston pumps and fluid dispense systems. Piston pumps use a series of pistons to push resin through a tube, ensuring consistent output. Fluid dispense systems rely on gravity to flow through a reservoir, providing a fine and even distribution. Both methods ensure consistent output, making them ideal for applications requiring accuracy.

Advantages of Using Epoxy Resin Dispensing Machines

- Precision: These machines deliver consistent results, crucial in industries like electronics where component failure can be costly.

- Reliability: They operate efficiently, reducing downtime and ensuring smooth production processes.

- Cost-Effectiveness: Longevity and reduced waste make them a cost-effective solution for manufacturers.

These benefits make them indispensable in various sectors, from automotive to aerospace, where reliability and precision are paramount.

Factors Affecting Precision and Efficiency

Several factors influence the performance of epoxy resin dispensing machines.

- Temperature Control: Temperature affects the viscosity of the resin. Proper temperature management ensures consistent output.

- Material Compatibility: Ensuring the resin is compatible with the machine and equipment prevents clogging and maintenance issues.

- Machine Calibration: Regular calibration is crucial for accurate measurements. Proper setup and maintenance enhance machine longevity.

Comparative Analysis: Automated vs. Manual Dispensing Methods

While manual methods offer flexibility, they can lead to inconsistencies. Automated systems, however, provide speed, consistency, and safety, making them ideal for high-volume production.

- Speed: Automated systems significantly reduce production time.

- Consistency: Automated systems minimize human error, ensuring uniform resin distribution.

- Safety: Automated systems reduce the risk of operator error, improving overall safety.

Tips for Selecting the Right Epoxy Resin Dispensing Machine

Choosing the right machine involves considering factors like material viscosity, cure time, and dispensing rate.

- Material Viscosity: High-viscosity resins require dispensing machines with greater pressure capability.

- Cure Time: Understanding the cure time of your resin helps in selecting a system that can handle the process efficiently.

- Dispensing Rate: High-rate dispensing is essential for large-scale operations, while compact units are suitable for small-scale applications.

Successful Implementation

A recent case study from the electronics industry highlights a factory that switched to an automated epoxy resin dispenser, reducing production time by 30% and waste by 20%. Another example from the aerospace sector shows improved accuracy in composite material layup, enhancing part quality and reducing scrap.

These successes demonstrate the tangible benefits of investing in quality dispensing machines.

!

!

The Future of Epoxy Resin Dispensing

Epoxy resin dispensing machines are pivotal in achieving precision and efficiency across industries. By understanding their working principles, leveraging their advantages, and selecting the right model, manufacturers can significantly enhance their operations. As technology advances, these machines will continue to play a crucial role in improving production processes.

In the future, we can expect even more advanced dispensing systems that integrate AI and IoT for real-time monitoring and predictive maintenance. Staying updated with these advancements ensures you can benefit from the latest improvements in precision and efficiency.

Stay ahead with the latest in epoxy resin dispensing technology and enhance your industrial processes today.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China