The Future of Epoxy Resin Dispensing with Modern Machines

The Rise of Epoxy Resin Dispensing Machines

The Evolution of Epoxy Resin Dispensing Machines

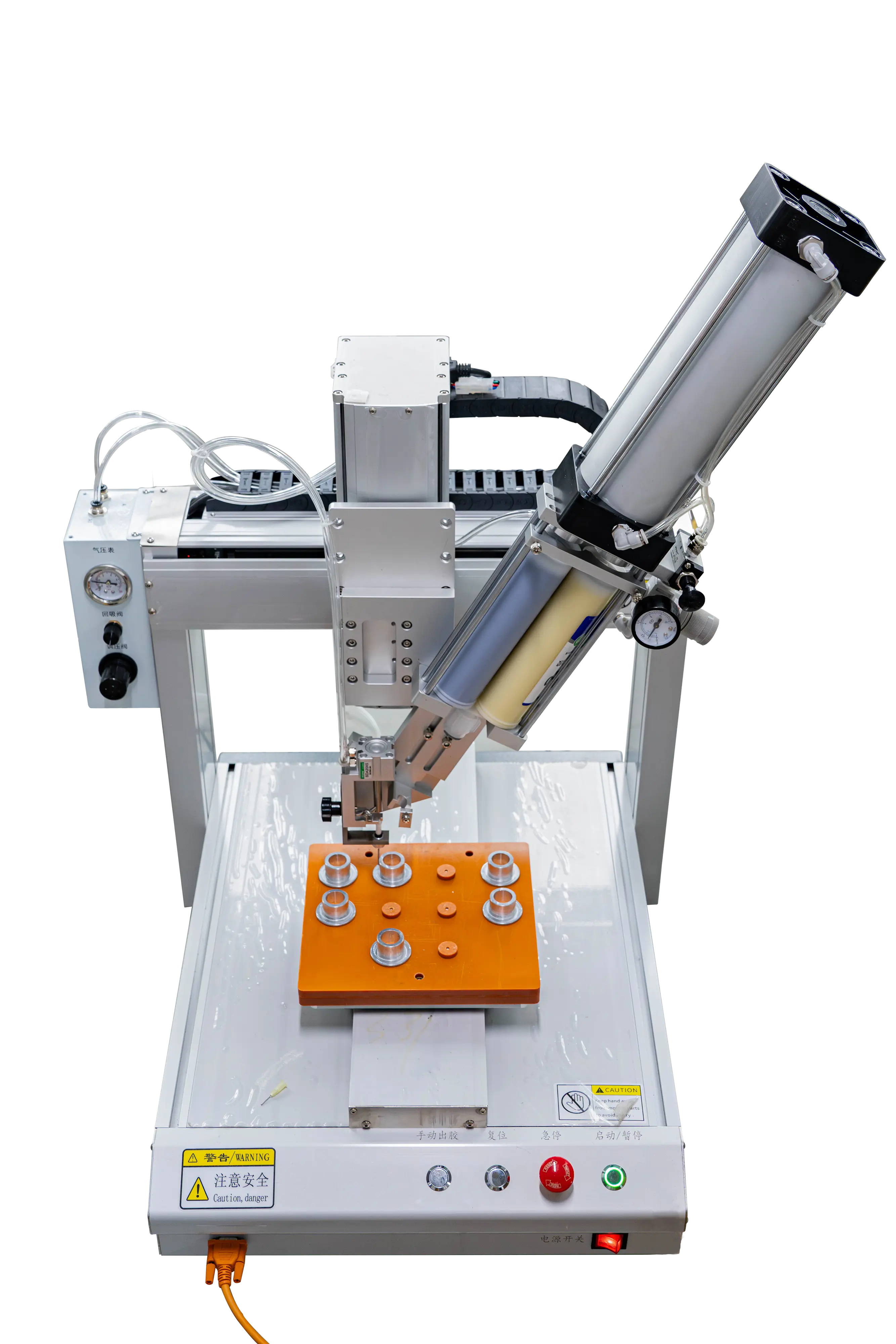

The journey from rudimentary dispensing methods to sophisticated machines has been marked by several key innovations. Modern machines now feature advanced precision control, enabling micro-level accuracy that was once unimaginable. The integration of automation has significantly boosted production speeds, allowing for 24/7 operations without human intervention. Additionally, these systems incorporate AI-driven algorithms that optimize performance based on real-time data, ensuring minimal downtime and waste. These advancements have not only enhanced product quality but also reduced costs, making epoxy resin dispensing more accessible and efficient across industries.

Precision and Consistency in Epoxy Resin Dispensing

Achieving precision and consistency is paramount in epoxy resin dispensing, especially in high-stakes industries like electronics. Modern machines utilize advanced sensors and feedback systems to ensure uniform application, minimizing waste and defects. Case studies from leading manufacturers highlight the significant improvements in product quality and yield when using automated dispensing systems. For instance, a semiconductor company reported a 20% reduction in material waste and a 15% increase in production efficiency after implementing these technologies. Such advancements underscore the importance of investing in modern machinery to maintain competitive edges.

Automation and Its Impact on Epoxy Resin Dispensing

Automation has become a cornerstone of contemporary epoxy resin dispensing. By automating repetitive tasks, these systems reduce human error and increase production efficiency. Manual systems often struggle with consistency and may require frequent recalibration, whereas automated systems operate seamlessly, even under varying conditions. Cost comparisons between manual and automated systems reveal that automation not only reduces operational costs but also enhances safety by eliminating the risk of human error. Furthermore, automated systems offer greater scalability, allowing businesses to meet fluctuating demand without compromising on quality.

Future Trends and Technological Innovations

Looking ahead, the epoxy resin dispensing industry is poised for further innovation. Upcoming technologies include the integration of robotics for complex dispensing tasks, machine learning for predictive maintenance, and IoT for real-time monitoring. These advancements promise to further enhance efficiency, reduce downtime, and enable smarter production processes. Additionally, the use of AI in optimizing machine performance will allow for personalized solutions tailored to specific industry needs, driving continuous improvement and innovation.

Environmental Considerations and Sustainable Practices

Sustainability is increasingly important in the epoxy resin dispensing industry. Modern machines are designed with eco-friendly materials, reducing their environmental footprint. Many companies are adopting closed-loop systems to minimize waste, ensuring that materials are reused and recycled effectively. Energy-efficient dispensing systems, powered by renewable energy sources, are also gaining traction, helping businesses reduce their carbon footprint. By embracing sustainable practices, companies can align with global environmental standards while enhancing their operational efficiency.

Challenges and Solutions in Implementing Modern Epoxy Resin Dispensing Machines

Transitioning to modern dispensing machines presents challenges such as high initial investment costs, the need for training, and the integration with existing systems. To address these barriers, companies should conduct thorough cost-benefit analyses to evaluate the payback period. Training programs should be comprehensive, ensuring that staff understand not only the operation of the machines but also best practices for maintaining and servicing them. Additionally, modular systems that can be easily integrated with existing infrastructure are ideal for businesses looking to implement these technologies gradually.

Embracing the Future of Epoxy Resin Dispensing

In conclusion, the future of epoxy resin dispensing lies in embracing modern technology for efficiency, precision, and sustainability. From automation to future innovations like AI and robotics, these advancements promise to shape the industry in ways that were previously unimaginable. However, companies must navigate the transition with a focus on cost, training, and sustainability to fully realize the potential of these technologies. By staying informed and proactive, businesses can harness the power of modern epoxy resin dispensing to achieve higher standards of quality, productivity, and environmental responsibility. Embracing this technological revolution is not just an industry need but a global imperative for sustainable growth.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China