Double station UV glue dispensing machine for plastic

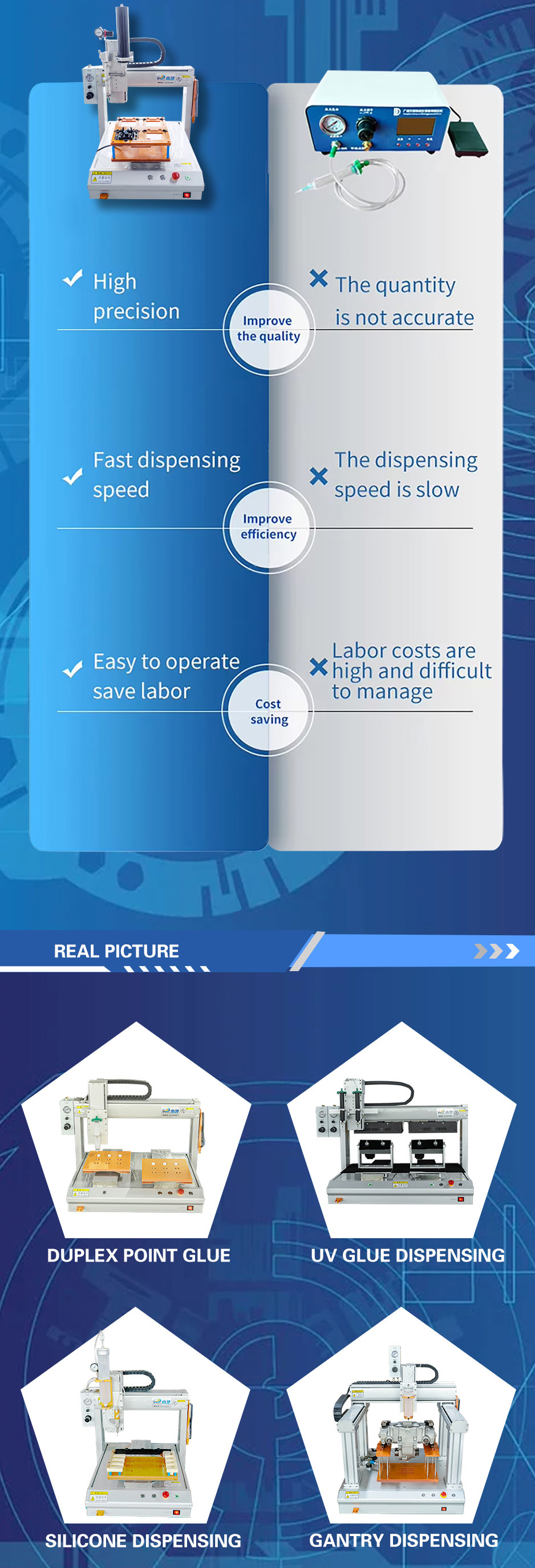

This double-station UV glue dispensing machine is an efficient device for plastic dispensing. The double-station design can work alternately, greatly improving production efficiency and reducing equipment idle time; the use of high-precision dispensing valves can accurately control the amount of glue and the dispensing position, and the glue is evenly discharged without drawing. The dispensing speed and dispensing amount can be set separately to ensure the stability of the dispensing quality and avoid problems such as overflow and lack of glue; equipped with a UV curing system, the high-energy UV lamp can complete the curing in as fast as 2 seconds, shortening the production cycle.

This equipment is suitable for many plastic product industries, such as plastic electronic component packaging, which can effectively protect the internal chip; plastic toy manufacturing, used for component bonding, to enhance the stability of the toy structure; plastic medical device assembly, to meet strict hygiene and precision requirements; and plastic jewelry processing, which can achieve fine and beautiful dispensing effects, improve product quality and market competitiveness.

1.Provide automated production solutions

2.24-hour global one-to-one efficient service.

3.Strong manufacturing, professional customization, quality assurance.

4.Have ISO, TUV and other international quality certifications.

5.Fast delivery, professional transportation.

6.On-site installation, simple and efficient.

Service:

Design and customize models, various styles, strong structure, support teaching, convenient transportation

Origin:

Shenzhen, Guangdong, China

Brand name:

Xiaomao Automation

More Choices

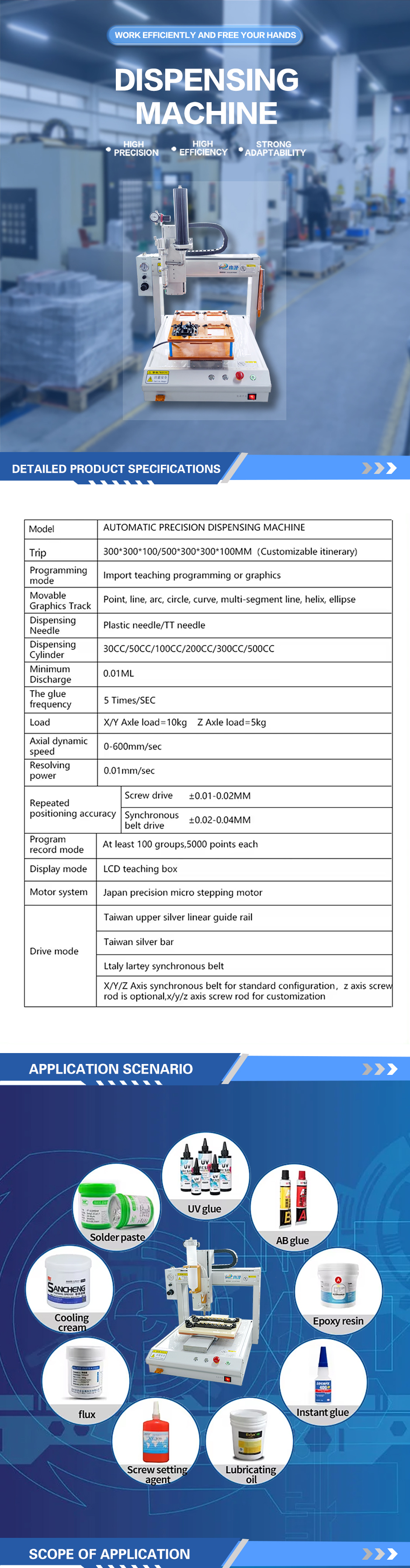

Model | UV Glue Dispensing Machine | |

Working range X/Y/Z (mm) | 300*300*100/500*300*300*100 ,Customizable stroke | |

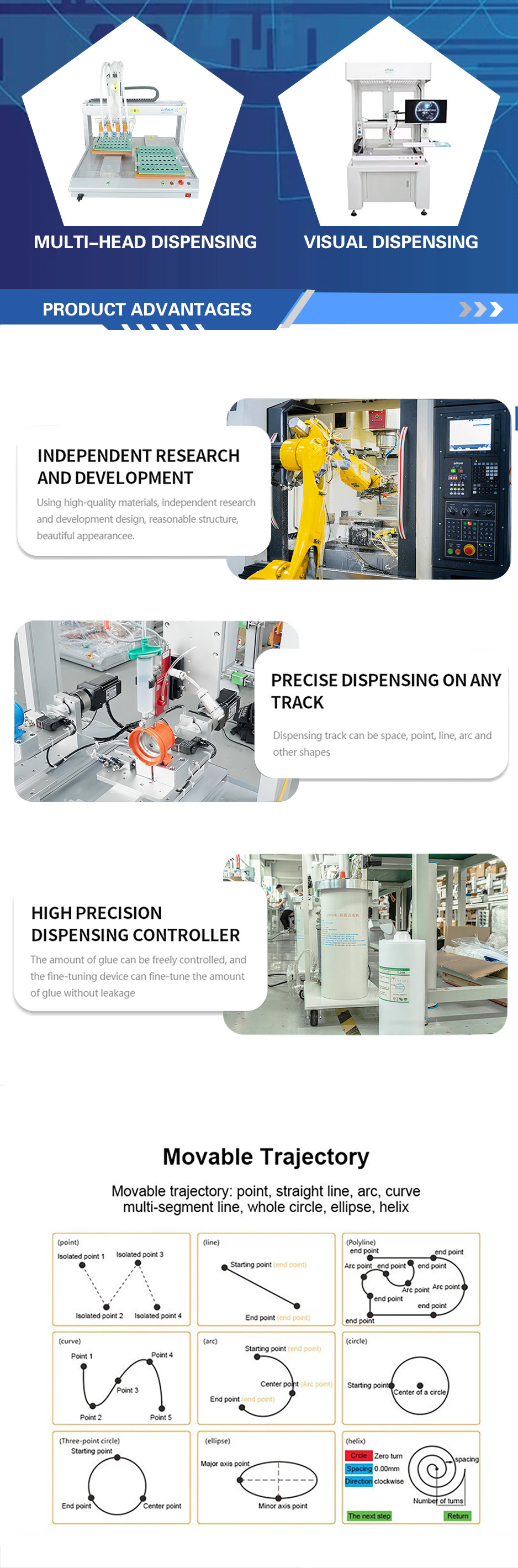

Programming method | Teaching programming or graphic import | |

Moving graphic trajectory | Point, straight line, arc, full circle, curve, polyline, spiral, ellipse | |

Dispensing needle | Plastic steel needle, TT needle | |

Dispensing cylinder | 30ml/50ml/300ml/5KG | |

Minimum discharge volume (mm) | 0.01 | |

Dispensing frequency (times/second) | 5 | |

Load (kg)

| X/Y axis | 10 |

Z axis | 5 | |

Weight (kg) | 48 | |

Motion system | Nihono stepper motor, driver | |

Operating system | LCD panel/handheld programmer | |

Repeat positioning accuracy (mm) | Screw drive | ±0.01-0.02 |

Synchronous belt | ±0.02-0.04 | |

Machine size (MM) | 540*580*650 | |

Program storage capacity | 999 parameter files (65,535 points per file) | |

Transmission method | Upper silver rail (slider) | |

Maximum speed (mm/s) | 300 | |

Marketing type | Ordinary product | |

Showroom location | Germany | |

Health condition | New | |

Warranty | 1 year | |

Core component warranty | 1 year | |

Mechanical test report | Provided | |

Video shipment inspection | Provided | |

Origin | Guangdong, China | |

Core components | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | |

Applicable glue | UV Glue | |

Applicable products

| Precision electronic components such as mobile phone cameras and sensors, optical devices such as optical lenses and filters, medical products such as medical catheters and microfluidic chips, and tiny parts of equipment such as vehicle-mounted radars and smart watches | |

Applicable industries | Electronic manufacturing, optics and optoelectronics, medical equipment, automotive electronics, semiconductor and new energy, etc. | |

FAQ

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China