Dual-station four-axis rotary automatic welding machine for PCB boards

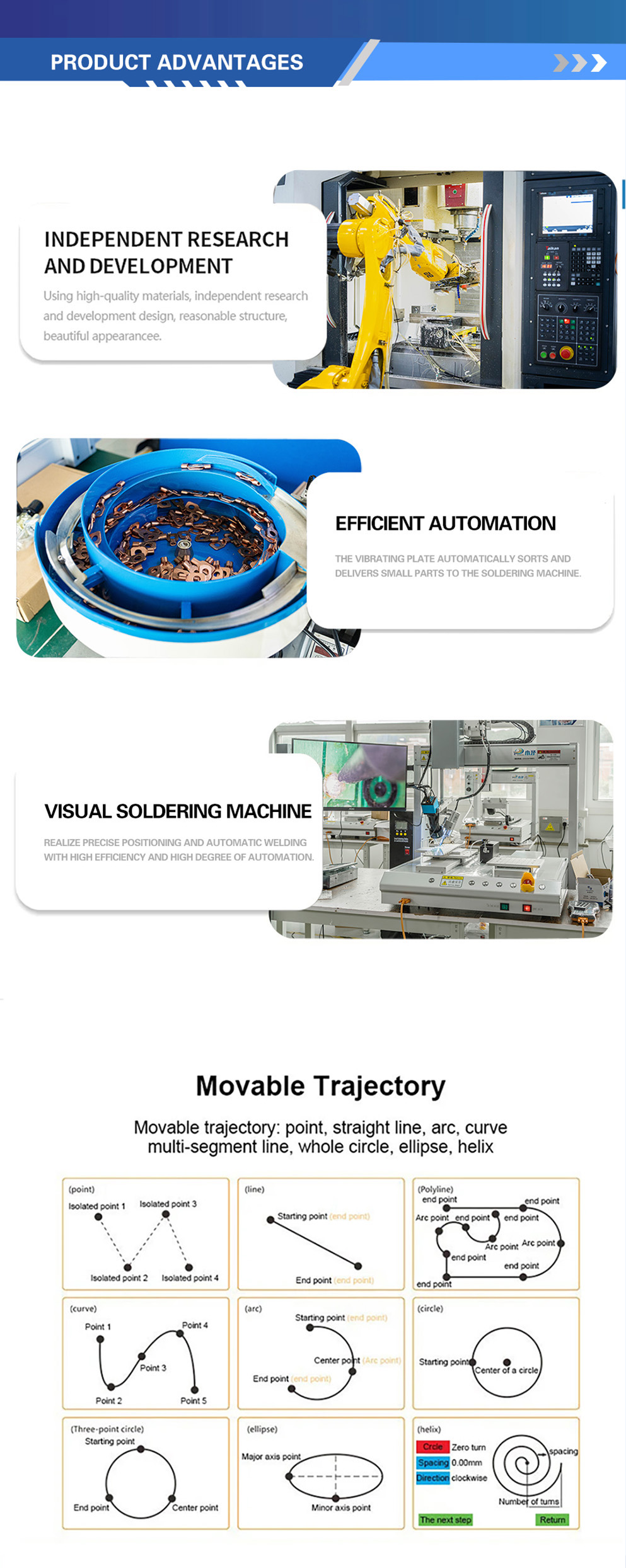

The Four Axis Auto Soldering & Welding Machine is an advanced solution for custom PCB manufacturing, offering precise and efficient soldering and welding capabilities. This machine is ideal for industries requiring high precision and quality in PCB production, such as electronics manufacturing and automotive industries. With its four-axis control system, this machine can handle complex soldering and welding tasks with ease, making it a valuable asset for improving production efficiency and quality control.

1.Providing automated production solutions.

2.Offering 24/7 one-on-one efficient service globally.

3.Manufacturing with strength, providing professional customization, and guaranteeing quality.

4.Possessing international quality certifications such as ISO and TUV.

5.Fast shipping and professional transportation.

6.On-site installation, simple and efficient.

Service:

Customized machine design with various models, sturdy structure, teaching support, and convenient transportation.

Origin:

Shenzhen, Guangdong Province, China

Brand Name:

Xiaomao Automation

More Choices

FAQ

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China