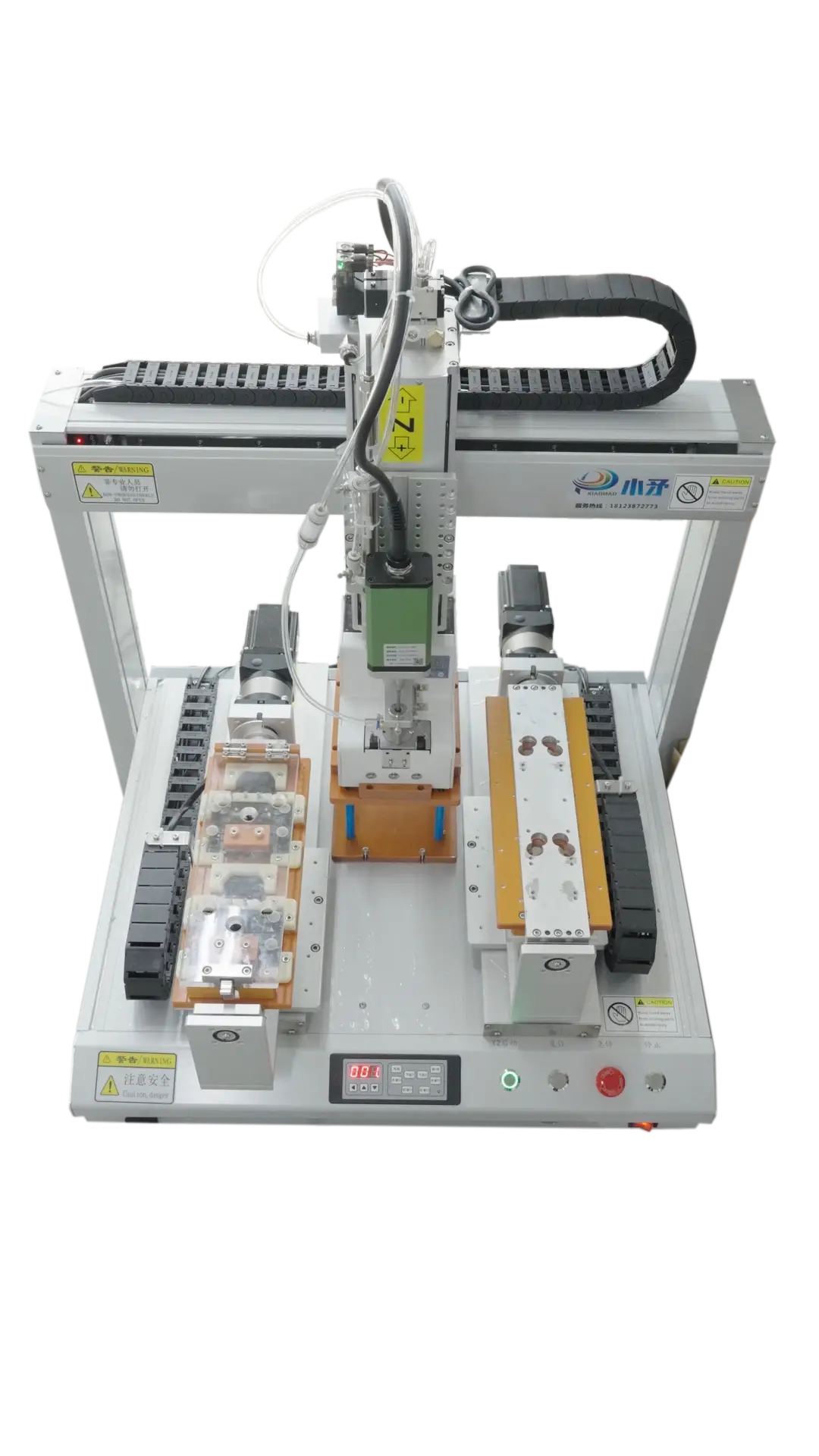

The Economic Impact of Adopting Automatic ScrewTechnology in Your Industry

How Automated Screws Boost Productivity

One of the primary advantages of introducing automated screw technology is its impact on productivity. Traditional assembly lines are often slow and prone to human error, which can slow down operations and increase production costs. By automating the screw insertion process, companies can significantly boost their output. For instance, a plant that previously required eight hours to assemble components can now complete the same task in just four hours. This not only saves time but also allows for faster response to customer demand and higher quality standards. The efficiency gains are substantial, with some companies reporting a 30% reduction in assembly time when switching to automated systems.

Financial Benefits of Automated Screws

Adopting automated screw technology comes with clear financial advantages. The cost of labor is a major expense for any manufacturing process, and automating the screw insertion process can significantly reduce these costs. By minimizing the need for manual intervention, companies can cut down on the training and hiring of additional workers. Additionally, the precision of automated systems reduces raw material wastage, leading to cost savings in inventory management. For example, a study conducted by the Manufacturing Institute found that companies adopting automated screw technology saw an average reduction of 25% in labor costs. Furthermore, the increased production speed and efficiency enable companies to scale their operations without incurring additional overhead. A factory that produces 500 components per hour can now produce 1,000 components per hour, doubling its output. This not only increases the production capacity but also allows for expanded market reach and higher profitability.

Automated Screws and Labor Cost Reductions

One of the most compelling reasons to adopt automated screw technology is the significant reduction in labor costs. By automating repetitive and labor-intensive tasks, companies can free up their human resources for more complex and value-added work. This not only cuts down on labor expenses but also allows for the hiring of more skilled workers who can operate the advanced machinery. For instance, a manufacturing plant that implemented automated screw technology reported a 25% reduction in labor costs and a 15% increase in overall efficiency. This shift allows companies to maintain high productivity levels while reducing operational expenses. Furthermore, the increased efficiency and reduced need for manual labor can free up employees to focus on other strategic initiatives, enhancing the company's operational capabilities.

Quality Improvement with Automated Screws

Another critical benefit of automated screw technology is its impact on product quality. Manual assembly is susceptible to human error, leading to defects and potential damage to a companys reputation. Automated systems, on the other hand, offer a higher level of precision and consistency. For example, a precision engineering company that relied on automated screw insertion saw a 15% reduction in defective products and a 5% increase in customer satisfaction rates. Consistent quality is essential for building trust with customers and reducing the costs associated with warranty claims and product recalls. Automated screw technology ensures that each component is inserted with the appropriate force and in the correct position, leading to fewer defects and higher customer satisfaction.

Successful Implementation of Automated Screw Technology

To illustrate the economic impact of automated screw technology, lets examine a couple of case studies.

1. Precision Engineering Company

A precision engineering firm initially struggled with inconsistent product quality and high defect rates due to manual screw insertion. After adopting automated screw technology, the company saw a 20% reduction in defective products, a 12% increase in production speed, and a 10% increase in customer satisfaction. The overall profitability of the company increased by 15%, making the transition a clear success. The companys commitment to continuous improvement and automation has transformed its operations and customer satisfaction levels.

2. Furniture Manufacturer

A furniture manufacturer faced delays in production due to manual screw insertion, leading to increased costs and customer dissatisfaction. By implementing automated screw technology, the company was able to reduce production time by 50% and achieve a 10% increase in production capacity. The reduction in defect rates and increased efficiency led to a 15% increase in sales and a 5% increase in profit margins. The company's focus on automation has not only improved its operations but has also strengthened its competitive position in the market.

Comparative Analysis: Automated vs. Manual Screw Insertion

A detailed comparison of automated and manual screw insertion reveals several advantages of automation. Automated systems are faster, more accurate, and less prone to errors than manual processes. Additionally, they require less training for workers, making them more efficient in the long run.

For example, while a manual assembler might take 15 minutes to insert a dozen screws, an automated system can do the same in just 2 minutes. This efficiency not only saves time but also allows companies to scale up their production without additional costs. Moreover, the precision of automated systems ensures that each screw is inserted correctly, reducing the likelihood of defects and improving overall product quality.

Challenges and Mitigation Strategies

While the benefits of automated screw technology are significant, the transition presents several challenges. The initial investment required to purchase and install the machinery can be substantial. Companies must conduct a thorough cost-benefit analysis to determine if the technology is a viable long-term investment. For instance, the upfront costs of installing an automated screw system can range from $50,000 to $200,000, depending on the complexity and scale of the operation.

Training is another potential hurdle. Companies must invest in training programs to ensure that workers are proficient in operating and maintaining the machinery. Additionally, proper maintenance and calibration of the equipment are essential to maximize its efficiency and prevent downtime. For example, regular calibration checks can reduce the likelihood of errors and extend the lifespan of the machinery.

The Future Prospects: The Role of IoT and AI in Assembly

The integration of Internet of Things (IoT) and Artificial Intelligence (AI) into assembly processes is expected to further enhance the economic impact of automated screw technology. IoT sensors can monitor machine performance in real-time, while AI algorithms can optimize production schedules and predict maintenance needs.

For example, an IoT-enabled assembly line can automatically adjust its speed based on workload, reducing energy consumption and operational costs. Similarly, AI-driven systems can analyze production data to identify inefficiencies and suggest process improvements. These innovations are expected to drive even greater economic benefits in the coming years. Companies that embrace these technologies can achieve even higher levels of efficiency and cost savings.

The Transformative Potential of Automated Screw Technology

In conclusion, the adoption of automated screw technology is a transformative step that can deliver significant economic benefits to industries. From increased productivity to reduced labor costs and enhanced product quality, automated screw technology is reshaping the way manufacturers operate.

By implementing automated screw technology, companies can achieve higher profitability, faster production, and greater customer satisfaction. Whether its a precision engineering firm, a furniture manufacturer, or any other industry, the economic impact of automated screw technology is undeniable.

As the world continues to evolve, companies that embrace the future of manufacturing will be better positioned to meet the demands of a rapidly changing market. The integration of advanced technologies like automated screw technology is not just an optionits a necessity for businesses that want to thrive in the modern industrial landscape.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China