Desktop hot melt adhesive dispensing machine with 5 kg heating cylinder preheating function

The four-axis rotary hot melt glue dispensing machine consists of a mechanical part (including the four-axis control system, rotary platform, transmission system, etc.), a hydraulic control part (such as a bidirectional hydraulic pump, throttle valve, etc.), and a dispensing control part (like pressure sensors, dispensing valves, etc.). By controlling the motion trajectories of four motors, it achieves translations along three coordinate axes (X, Y, Z) and rotation around one axis, thereby enabling precise control of the position and angle of glue application. This high-precision control ensures the accuracy and consistency of the dispensing process. The incorporation of the rotary axis allows the dispensing machine to handle products with complex shapes more flexibly, enabling rapid and continuous dispensing operations. It is suitable for various types of products and different dispensing needs for shapes such as the inner and outer walls of products, vertical surfaces, gaps, spherical curved surfaces, and more. Compared to manual dispensing, the four-axis rotary hot melt glue dispensing machine can significantly improve production efficiency, and it has broad application prospects and significant value in the field of industrial automation.

1.Providing automated production solutions.

2.Offering 24/7 one-on-one efficient service globally.

3.Manufacturing with strength, providing professional customization, and guaranteeing quality.

4.Possessing international quality certifications such as ISO and TUV.

5.Fast shipping and professional transportation.

6.On-site installation, simple and efficient.

Service:

Customized machine design with various models, sturdy structure, teaching support, and convenient transportation.

Origin:

Shenzhen, Guangdong Province, China

Brand Name:

Xiaomao Automation

More Choices

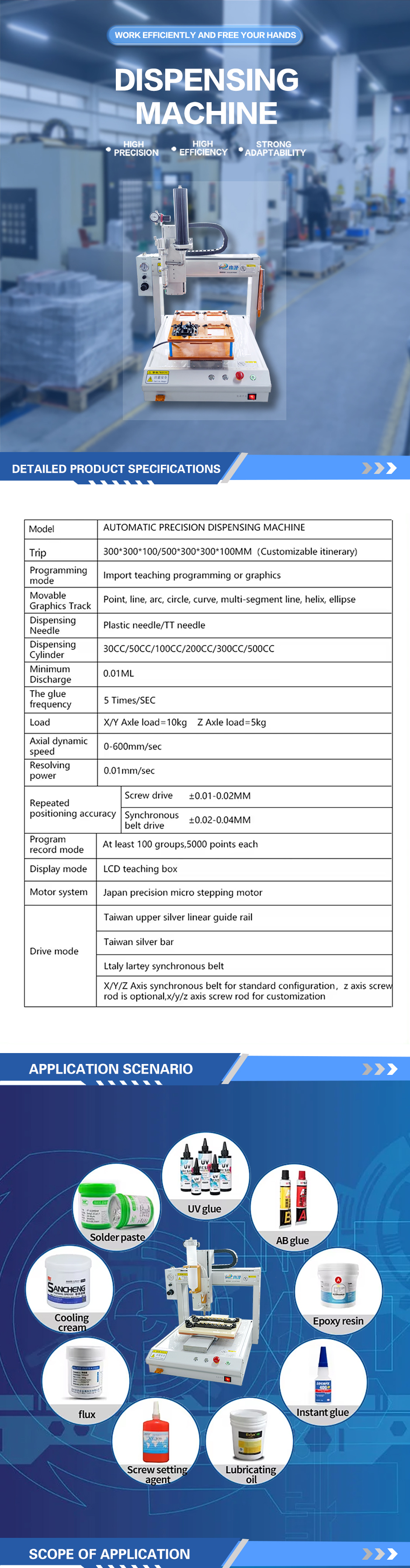

Model | Automatic dispensing machine | |

Working range X/Y/Z (mm) | 300*300*100/500*300*300*100 Customizable stroke | |

Programming method | Teaching programming or graphic import | |

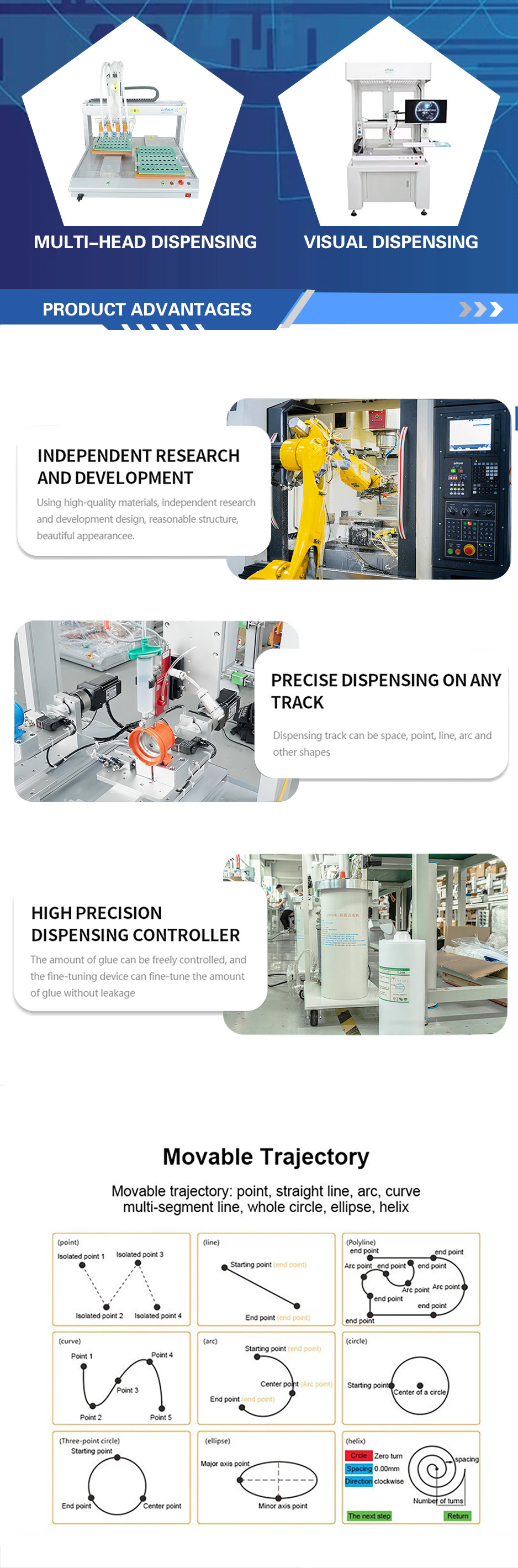

Moving graphic trajectory | Point, straight line, arc, full circle, curve, polyline, spiral, ellipse | |

Dispensing needle | Plastic steel needle, TT needle | |

Dispensing cylinder | 30CC/50CC/100CC/200CC/300CC/500CC | |

Minimum discharge volume (mm) | 0.01 | |

Dispensing frequency (times/second) | 5 | |

Load (kg)

| X/Y axis | 10 |

Z axis | 5 | |

Weight (kg) | 48 | |

Motion system | Nihono stepper motor, driver | |

Operating system | LCD panel/handheld programmer | |

Repeat positioning accuracy (mm) | Screw drive | ±0.01-0.02 |

Synchronous belt | ±0.02-0.04 | |

Machine size (MM) | 540*580*650 | |

Program storage capacity | 999 parameter files (65,535 points per file) | |

Transmission method | Upper silver rail (slider) | |

Maximum speed (mm/s) | 300 | |

Marketing type | Ordinary product | |

Showroom location | Germany | |

Health condition | New | |

Warranty | 1 year | |

Core component warranty | 1 year | |

Mechanical test report | Provided | |

Video shipment inspection | Provided | |

Origin | Guangdong, China | |

Core components | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | |

Applicable glue | UV glue, AB glue, black glue, white glue, yellow glue, EMI conductive glue, anaerobic glue, epoxy resin, instant glue, silver glue, red glue, solder paste, heat dissipation paste, solder mask, transparent paint, lubricating oil, flux, screw fixing agent, etc. | |

Applicable products

| Sensors, relays, power adapters, electronic toys, buzzers, electronic components, household appliances, toys, stationery, electric vehicle controllers, computer digital products, handicrafts, mobile phone boards, coil products, key products, battery boxes, speaker outer ring dispensing and bonding, etc | |

Applicable industries | hotels, clothing stores, building materials stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, restaurants, home use, retail, food stores, printing shops, construction projects, energy and mining, food and beverage stores, advertising companies, etc | |

FAQ

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China