Single station 300ml hot melt adhesive dispensing machine

2.24-hour global one-to-one efficient service.

3.Strong manufacturing, professional customization, quality assurance.

4.Have ISO, TUV and other international quality certifications.

5.Fast delivery, professional transportation.

6.On-site installation, simple and efficient.

Service:

Design and customize models, various styles, strong structure, support teaching, convenient transportation

Origin:

Shenzhen, Guangdong, China

Brand name:

Xiaomao Automation

More Choices

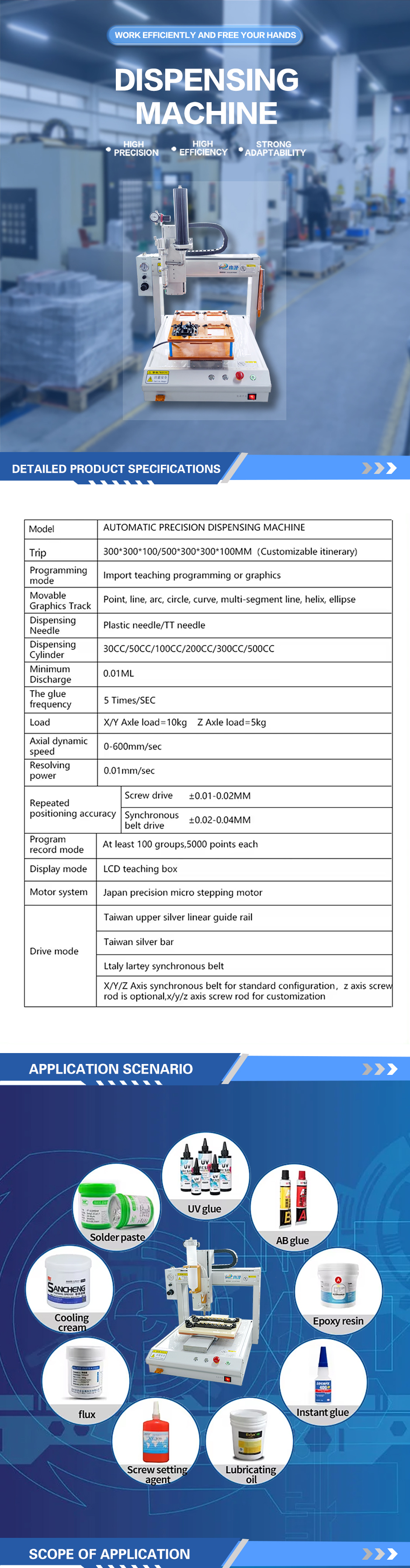

Model | Automatic dispensing machine | |

Working range X/Y/Z (mm) | 300*300*100/500*300*300*100 ,Customizable stroke | |

Programming method | Teaching programming or graphic import | |

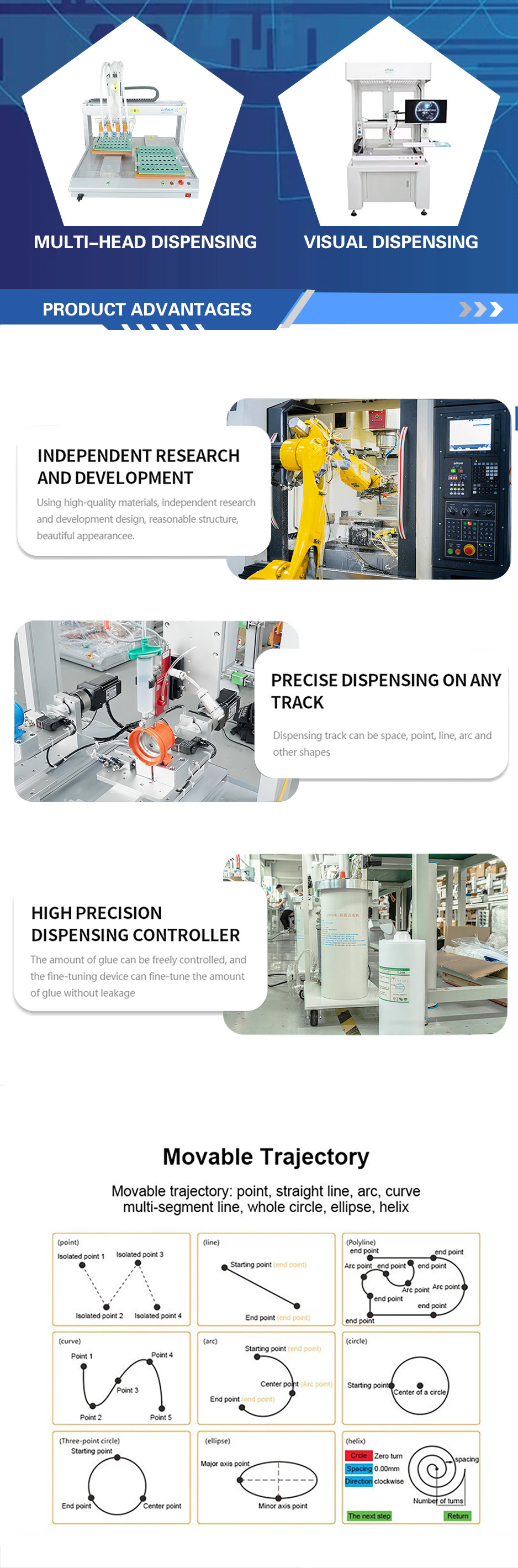

Moving graphic trajectory | Point, straight line, arc, full circle, curve, polyline, spiral, ellipse | |

Dispensing needle | Plastic steel needle, TT needle | |

Dispensing cylinder | 30ml/50ml/300ml/5KG | |

Minimum discharge volume (mm) | 0.01 | |

Dispensing frequency (times/second) | 5 | |

Load (kg)

| X/Y axis | 10 |

Z axis | 5 | |

Weight (kg) | 48 | |

Motion system | Nihono stepper motor, driver | |

Operating system | LCD panel/handheld programmer | |

Repeat positioning accuracy (mm) | Screw drive | ±0.01-0.02 |

Synchronous belt | ±0.02-0.04 | |

Machine size (MM) | 540*580*650 | |

Program storage capacity | 999 parameter files (65,535 points per file) | |

Transmission method | Upper silver rail (slider) | |

Maximum speed (mm/s) | 300 | |

Marketing type | Ordinary product | |

Showroom location | Germany | |

Health condition | New | |

Warranty | 1 year | |

Core component warranty | 1 year | |

Mechanical test report | Provided | |

Video shipment inspection | Provided | |

Origin | Guangdong, China | |

Core components | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | |

Applicable glue | PUR hot melt adhesive, PUH hot melt adhesive, hot melt adhesive granules, hot melt adhesive sticks, hot melt adhesive blocks, hot melt adhesive powder | |

Applicable products

| Woodworking, gift boxes, boutique boxes, toys, leather, leather goods, electronics, electrical appliances, carton edge banding, label reinforcement, interior bonding, filter sealing, circuit board packaging, wiring harness fixing, furniture splicing, mattress bonding, non-woven fabric lamination, shoe assembly, dressing production, equipment packaging, photovoltaic module packaging, lithium battery tab bonding, insulation board bonding, door and window sealing, book binding, packaging box molding, etc. | |

Applicable industries | Packaging, automobile manufacturing, electronics and electrical appliances, household goods, textiles and clothing, medical treatment, toys, new energy, construction materials, printing, etc. | |

FAQ

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China