Spot-On Resin Dispensing: A Comprehensive How-To Guide

Resin dispensing is a critical process in various industries, including construction, automotive, and manufacturing. It involves the precise application of resin material to create durable and long-lasting surfaces, ensuring consistency in thickness, coverage, and finish. As resin technology continues to evolve, so too do the methods and techniques used to ensure optimal results. This guide will walk you through the essential aspects of resin dispensing, from equipment selection to troubleshooting common issues.

Understanding the Essence of Resin Dispensing

Resin dispensing is the process of applying resin material through a nozzle or syringe under pressure to create a uniform layer. The primary goal is to ensure consistency and precision in the application of resin. The importance of resin dispensing lies in its versatility and wide range of applications. For instance, in the construction industry, resin is used to create durable concrete floors and countertops. In automotive repair, it is used to apply resin linings for engine blocks and cylinders. In manufacturing, it is used to produce intricate parts for machinery and fixtures.

According to a report by Market Research Engine, the global resin dispensing market is expected to grow at a CAGR of 5.2% from 2022 to 2029. This growth is driven by the increasing demand for high-quality, durable, and long-lasting materials in various industries. Understanding the nuances of resin dispensing is crucial for achieving these results.

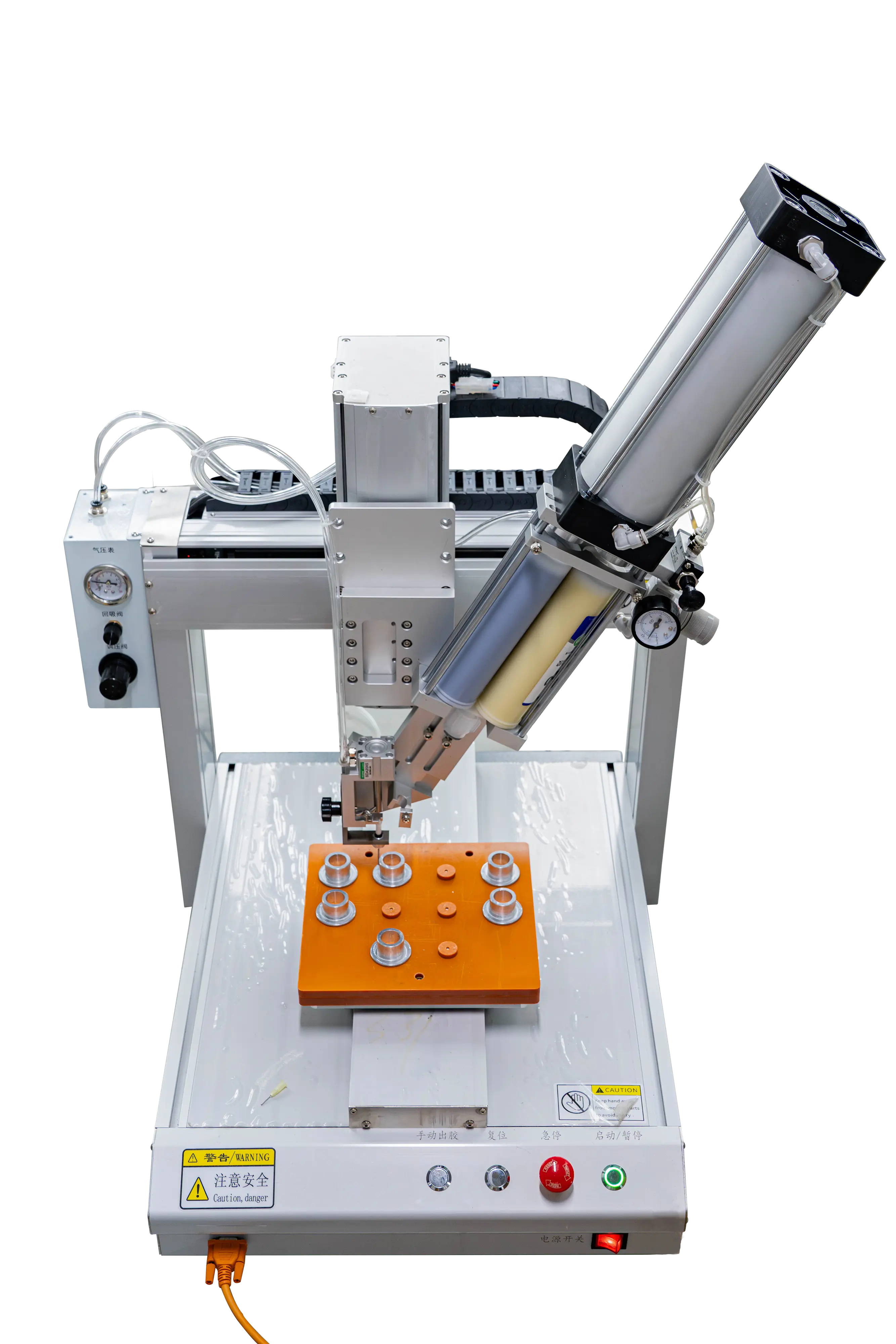

Key Components and Equipment for Resin Dispensing

The success of a resin dispensing process depends on the quality and functionality of the equipment used. Below is an overview of the essential components and tools required for resin dispensing:

1. Resin Vessels: Resin is typically stored in specialized vessels designed to hold large volumes of material. These vessels are usually made of polypropylene or stainless steel to ensure durability and resistance to chemical attack. Proper storage ensures that the resin remains stable and ready for use.

- Syringes and Nozzles: Syringes are used to draw resin from the vessel, while nozzles are used to atomize the resin into a fine mist or stream. The type of nozzle used depends on the desired finish and thickness of the layer being applied. A high-quality nozzle can significantly improve the consistency and quality of the finish.

- Pressure Regulator: A pressure regulator is used to control the flow of resin through the syringe and nozzle. Proper pressure is essential to ensure consistency and prevent overflows or underflows. Regular calibration of the pressure regulator ensures accurate dispensing.

- Controller: A resin dispensing controller is a computerized system that monitors and controls the dispensing process. It can adjust pressure, speed, and temperature in real-time to ensure optimal results. Advanced controllers can also provide real-time data and analytics, enabling precise control and consistent outcomes.

- Filters and Sensors: Filters and sensors are used to maintain the cleanliness of the equipment and monitor the performance of the system. Regular maintenance and cleaning of the equipment can help prevent contamination and ensure the longevity of the equipment. Sensors can detect issues such as pressure changes or flow irregularities, providing early warnings to prevent potential problems.

By understanding the role of each component, you can select the right equipment for your specific needs and ensure a smooth and efficient dispensing process.

Techniques for Precise Resin Dispensing

Resin dispensing can be performed using various techniques, each suited to different applications and requirements. Below are the most common techniques used in resin dispensing:

1. Drop Dispensing: This technique involves the application of resin in small, individual droplets. Drop dispensing is ideal for creating intricate patterns and detailed finishes. However, it requires precise control over the size and shape of the droplets to ensure consistency. Using a high-precision syringe and a fine nozzle can help achieve the desired results.

2. Line Dispensing: Line dispensing is used for creating uniform layers of resin in a straight line. This technique is commonly used in applications such as countertop installation and flooring. The pressure and speed of the dispensing process can be adjusted to achieve the desired thickness and finish. A line dispensing system can help ensure uniform layers and a smooth finish.

3. Volume Control Dispensing: Volume control dispensing involves the application of resin at a fixed rate, typically measured in gallons per minute (GPM). This technique is ideal for large-scale applications where consistency is key, such as in the construction industry. A programmable controller can be used to maintain a consistent flow rate, ensuring uniform coverage and a high-quality finish.

Each technique has its own advantages and limitations, and the choice of technique depends on the specific requirements of the project. By mastering these techniques, you can achieve precise and reliable results in a wide range of applications.

Troubleshooting Common Issues in Resin Dispensing

Despite the best efforts, issues can arise during the resin dispensing process. Below are some common problems and their solutions:

1. Inconsistent Flow: Inconsistent flow can lead to uneven layers and poor finish quality. To address this issue, ensure that the pressure regulator is functioning properly and that the nozzle is clean and free of blockages. Regular calibration of the pressure regulator can help maintain consistent pressure throughout the dispensing process.

2. Clogging: Resin clogging is a common problem that can occur due to debris, scale buildup, or improper cleaning. Regular maintenance and cleaning of the equipment can help prevent clogging. Using a degassing agent can help remove any trapped air or gas in the resin before dispensing. Proper cleaning and maintenance schedules can ensure that your equipment remains in optimal condition.

3. Uneven Discharge: Uneven discharge can result in an uneven layer of resin, which can affect the finish and strength of the product. To fix this issue, ensure that the equipment is level and that the nozzle is aligned properly. Adjusting the pressure and speed of the dispensing process can help achieve a more uniform layer. Proper alignment and leveling can prevent uneven discharge and improve the finish.

4. Residue or Overflow: Residue or overflow can occur if the pressure is too high or if the equipment is not properly sealed. To prevent this, ensure that the equipment is properly sealed and that the pressure is adjusted to the appropriate level for the application. Proper sealing and pressure adjustment can help minimize residue and overflow, ensuring a clean and efficient process.

By addressing these common issues, you can improve the efficiency and quality of your resin dispensing process.

Safety and Environmental Considerations in Resin Dispensing

Resin dispensing involves the use of hazardous materials, including resins, solvents, and cleaning agents. As such, it is essential to follow safety protocols and environmental guidelines to protect yourself and the environment. Below are some key considerations:

1. Safety Protocols: Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and a lab coat, to protect yourself from exposure to resins and cleaning agents. Ensure that you are working in a well-ventilated area and avoid prolonged exposure to open flames or sparks. Safety training and regular drills can help ensure that you and your team are prepared for any contingencies.

2. Environmental Compliance: Resin disposal must be done in accordance with local and national regulations. Dispose of residual resins and solvents in approved waste disposal facilities to minimize environmental impact. Using eco-friendly cleaning agents and disposing of waste in approved facilities can help reduce the environmental footprint of your operations. Compliance with safety and environmental regulations is crucial for maintaining a sustainable and responsible work environment.

3. Hazardous Material Handling: Handle all hazardous materials with care and follow proper disposal procedures. Avoid mixing resins with incompatible materials, as this can lead to chemical reactions that produce harmful byproducts. Proper handling and storage of hazardous materials can help prevent accidents and ensure a safe work environment.

By adhering to safety and environmental guidelines, you can minimize risks and contribute to the sustainability of your operations.

Real-World Applications and Success Stories

Resin dispensing has been successfully applied in a wide range of industries, from construction to automotive repair. Below are some real-world case studies that highlight the benefits of resin dispensing:

1. Construction Industry: In the construction industry, resin dispensing is used to create durable concrete floors and countertops. A case study of a high-rise building in New York City demonstrated that the use of resin dispensing resulted in a 20% improvement in surface strength and a 15% reduction in labor costs compared to traditional methods. This case study highlights the cost savings and improved durability that can be achieved through the use of resin dispensing.

2. Automotive Repair: In the automotive repair industry, resin dispensing is used to apply resin linings for engine blocks and cylinders. A case study of a car manufacturing plant in Germany showed that the use of resin dispensing improved the durability of the engine components by 30% and reduced the risk of warping and cracking. This case study demonstrates how resin dispensing can enhance performance and reduce maintenance costs in the automotive industry.

3. Manufacturing: In manufacturing, resin dispensing is used to produce intricate parts for machinery and fixtures. A case study of a hardware manufacturing company in Taiwan demonstrated that the use of resin dispensing resulted in a 25% increase in production efficiency and a 10% reduction in material waste. This case study highlights the potential for increased productivity and reduced waste in manufacturing operations.

These case studies highlight the versatility and effectiveness of resin dispensing in real-world applications.

Tips and Best Practices for Optimal Resin Dispensing

To achieve the best results in resin dispensing, follow these tips and best practices:

1. Maintenance: Regular maintenance of your equipment is essential to ensure optimal performance. Clean and inspect the equipment regularly, and replace worn-out parts as needed. Proper maintenance can help prevent issues and extend the lifespan of your equipment.

2. Calibration: Proper calibration of your equipment is crucial for achieving consistent results. Ensure that the pressure, speed, and temperature settings are adjusted to the specific requirements of your application. Regular calibration can help maintain the accuracy and precision of your dispensing process.

3. Training: Training your team on the proper use of equipment and safety protocols can help ensure consistent results and minimize risks. Conduct regular safety drills and provide hands-on training to your team. Training ensures that everyone is familiar with the equipment and understands the best practices for safe and effective use.

4. Quality Control: Implement quality control measures to monitor the performance of your dispensing process. Regular inspections and testing can help identify and address any issues before they escalate. Quality control ensures that your products meet the highest standards of quality and performance.

5. Eco-Friendly Practices: Be mindful of environmental impact and follow regulations for the disposal of hazardous materials. Use eco-friendly cleaning agents and dispose of waste in approved facilities. Eco-friendly practices not only reduce your environmental footprint but also demonstrate a commitment to sustainability.

By following these tips and best practices, you can achieve optimal results in resin dispensing and contribute to the sustainability of your operations.

The Future of Resin Dispensing

Resin dispensing is a rapidly evolving field, with new technologies and techniques being developed to improve efficiency, accuracy, and sustainability. As the demand for durable and high-quality materials continues to grow, resin dispensing will play an increasingly important role in various industries.

Looking ahead, the future of resin dispensing is exciting. Advances in automation, artificial intelligence, and material science will further enhance the capabilities of resin dispensing systems. For instance, automated systems can help reduce labor costs and improve consistency. Artificial intelligence can provide real-time data and analytics, enabling more precise control and optimal outcomes. Additionally, the increasing focus on environmental sustainability will drive the development of greener and more efficient resin dispensing technologies.

By staying informed about the latest advancements and adhering to best practices, you can ensure that your resin dispensing operations remain competitive and sustainable in the long term.

This concludes our comprehensive guide to resin dispensing. Whether you're a novice or an experienced professional, this guide provides the insights and tips you need to master the art of resin dispensing.

E-MAIL:

Floor 6, Building A, Concept Space Automobile Industrial Park, No. 76, Ainan Road, Baolong Street, Longgang District, Shenzhen,China